MZ ELECTRONIC

PRODUCTS

MZ ELECTRONIC ·

MZ ELECTRONIC

ABOUT US

Wuhan MZ Electronic Co., Ltd

Wuhan MZ Electronic is a leading manufacturer specializing in the production of high-quality cable management solutions.With a focus on innovation and quality, we have established ourselves as a trusted supplier in the industry.

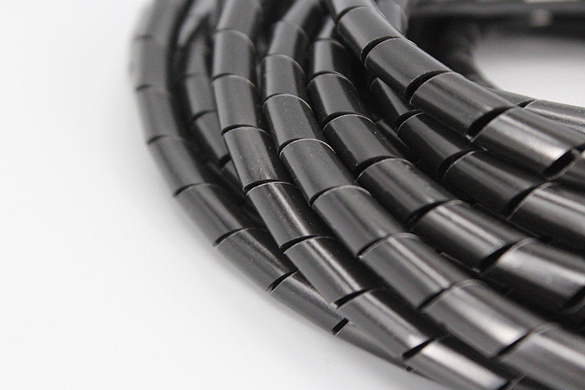

Our products range focus on the cable management, ranging of nylon cable ties, hook and loop cable ties, stainless steel cable ties, cable clips, cable glands, cable tie mounts, cable holders, wire connectors, spiral wrapping band and other cable/wiring accessories.

READ MORE →MZ ELECTRONIC

HOT PRODUCT

MZ ELECTRONIC

SUPPORT

MZ ELECTRONIC

NEWS CENTER

Operation method of pneumatic shearing machine

Pneumatic strap cutters are essential tools in various industries, from packaging and shipping to manufacturing and construction. These devices offer efficient and precise cutting of different types of straps, such as plastic, steel, or polyester straps. To ensure safe and effective operation, it's crucial to understand the proper usage of a pneumatic strap cutter. Here's a step - by - step guide.

19

2026-01

Electric Cable Tie Gun Operating Instructions

An electric cable tie gun is a handy tool that simplifies the process of securing cable ties, making it faster and more efficient compared to manual methods. Whether you're working on electrical installations, organizing cables in a data center, or bundling items for shipping, understanding how to properly use an electric cable tie gun is essential. Here's a detailed guide to help you get started.

19

2026-01

The precise tension control method for cable guns

When working with cable tie guns, achieving the right tension is crucial for ensuring secure and professional-looking installations. Whether you're bundling cables, securing equipment, or organizing items, precise tension control prevents over-tightening, which can damage delicate components, and under-tightening, which may lead to loosening over time. Here are some effective methods to help you master precise tension control with a cable tie gun.

18

2026-01

The technique for cutting plastic cable ties using diagonal pliers

Plastic cable ties are widely used for bundling and securing items, but cutting them cleanly and safely requires the right approach, especially when using diagonal cutting pliers. Here are some practical techniques to ensure efficient and precise cutting every time.

18

2026-01

Selection of plastic cable ties cutting tools

When working with plastic cable ties, having the right cutting tool ensures efficiency, safety, and a clean finish. Whether you're organizing cables, securing items, or managing DIY projects, choosing the appropriate tool for trimming excess cable tie material is essential. Here’s a detailed breakdown of the key factors to consider when selecting a plastic cable tie cutting tool.

17

2026-01