19

2026

-

01

Operation method of pneumatic shearing machine

Author:

A Comprehensive Guide to Using Pneumatic Strap Cutters

Pneumatic strap cutters are essential tools in various industries, from packaging and shipping to manufacturing and construction. These devices offer efficient and precise cutting of different types of straps, such as plastic, steel, or polyester straps. To ensure safe and effective operation, it's crucial to understand the proper usage of a pneumatic strap cutter. Here's a step - by - step guide.

Pre - Use Setup

Connecting to the Air Supply

The first step in using a pneumatic strap cutter is to connect it to a reliable air supply. Locate the air inlet on the cutter, which is usually a quick - connect fitting. Ensure that the air compressor is turned on and set to the appropriate pressure level as specified in the user manual. Typically, the required pressure ranges from 60 to 100 PSI (pounds per square inch), but this can vary depending on the model and the type of strap being cut. Connect the air hose firmly to the inlet, making sure there are no air leaks. You can check for leaks by applying a small amount of soapy water around the connection points; if bubbles form, there's a leak that needs to be fixed.

Selecting the Right Blade

Different straps may require different types of blades for optimal cutting performance. For example, a sharp, thin blade is suitable for cutting plastic straps, while a thicker, more durable blade may be needed for steel straps. Check the user manual to determine the recommended blade type for the specific straps you'll be working with. Install the blade carefully according to the manufacturer's instructions. Make sure it is securely fastened in place to prevent it from coming loose during operation, which could lead to accidents or poor cutting results.

Adjusting the Cutting Depth (if applicable)

Some pneumatic strap cutters allow you to adjust the cutting depth. This feature is useful when you want to make a clean cut without damaging the underlying surface or the object being strapped. Locate the depth adjustment mechanism, which could be a dial, a lever, or a screw - type adjustment. Refer to the user manual to understand how to make the necessary adjustments. Start with a conservative setting and test the cut on a spare piece of strap to ensure that the cutting depth is appropriate.

Basic Operation Steps

Positioning the Strap

Place the strap to be cut in the designated cutting area of the pneumatic strap cutter. Ensure that the strap is flat and properly aligned. If the strap is twisted or not positioned correctly, it may result in an uneven cut or damage to the blade. For steel straps, be especially careful to avoid any kinks or bends that could affect the cutting process. Keep your fingers and other body parts away from the cutting area to prevent injuries.

Activating the Cutter

Once the strap is in position, you can activate the pneumatic strap cutter. Depending on the model, there may be a trigger, a button, or a foot pedal to initiate the cutting action. If it's a trigger - operated cutter, squeeze the trigger firmly and steadily. For button - operated models, press the button with enough force to start the cutting cycle. If using a foot pedal, step on it firmly to activate the cutter. As the cutter starts to operate, you'll hear the sound of the compressed air driving the blade.

Monitoring the Cutting Process

While the cutter is in operation, closely monitor the cutting process. Ensure that the blade is cutting through the strap smoothly and evenly. If you notice any issues, such as the blade getting stuck or the strap not being cut completely, stop the operation immediately. Check for any obstructions, such as debris or a misaligned strap, and make the necessary adjustments before continuing. Do not force the cutter to cut through the strap if it's encountering resistance, as this could damage the tool or cause safety hazards.

Advanced Usage Techniques

Cutting Multiple Straps Efficiently

In some situations, you may need to cut multiple straps in a short period. To improve efficiency, you can stack the straps neatly and adjust the cutting depth and position of the cutter accordingly. Make sure the straps are aligned properly to ensure consistent cutting. When cutting multiple straps, be aware that the cutting force required may increase, so you may need to adjust the air pressure slightly if the cutter is not performing as expected.

Cutting Straps at an Angle

There may be instances where you need to cut straps at an angle, such as when creating a beveled edge for a better fit or for aesthetic purposes. To achieve an angled cut, you can use a jig or a guide to position the strap at the desired angle before activating the cutter. Alternatively, some pneumatic strap cutters may have adjustable cutting heads that allow you to change the cutting angle. Refer to the user manual to see if your cutter has this feature and how to use it.

Dealing with Thick or Tough Straps

When working with thick or tough straps, such as heavy - duty steel straps, you may encounter some challenges. First, ensure that the blade is sharp and in good condition. A dull blade will struggle to cut through thick straps and may cause the cutter to malfunction. You may also need to increase the air pressure slightly to provide more cutting force. However, be careful not to exceed the maximum recommended air pressure for your cutter, as this could damage the tool. If the strap is extremely thick, consider making multiple passes with the cutter, gradually cutting deeper each time.

Post - Use Maintenance

Cleaning the Cutter

After using the pneumatic strap cutter, it's important to clean it to remove any debris, strap fragments, or lubricant residue. Use a soft brush or compressed air to clean the cutting area, the blade, and the air inlet and outlet. Wipe down the exterior of the cutter with a clean, dry cloth. Regular cleaning helps prevent the buildup of dirt and debris that could affect the performance of the tool and cause premature wear.

Lubricating Moving Parts

Lubricating the moving parts of the pneumatic strap cutter is essential for maintaining its smooth operation. Apply a small amount of pneumatic tool oil to the pivot points, the blade mechanism, and other moving parts as recommended in the user manual. Be careful not to over - lubricate, as excess oil can attract dirt and debris and cause clogging.

Storing the Cutter Properly

Store the pneumatic strap cutter in a dry, clean place away from direct sunlight and extreme temperatures. If possible, keep it in its original case or a suitable protective container to prevent damage. Disconnect the air hose and release any remaining air pressure in the cutter before storing it. This helps prevent damage to the internal components and ensures that the cutter is ready for use the next time you need it.

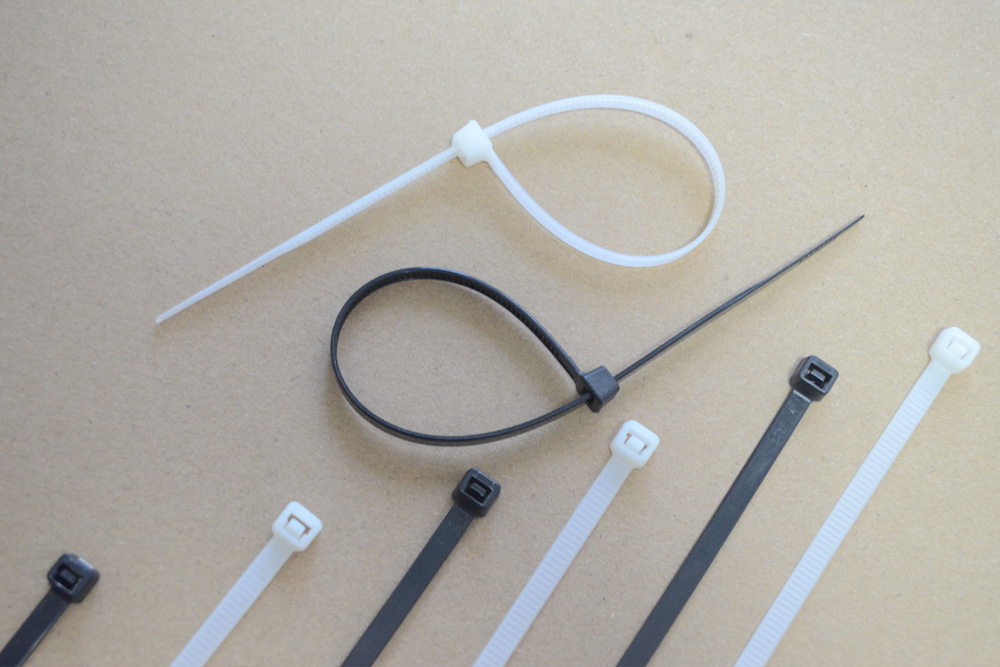

plastic cable ties

Hot News

2026-01-19

Operation method of pneumatic shearing machine

Pneumatic strap cutters are essential tools in various industries, from packaging and shipping to manufacturing and construction. These devices offer efficient and precise cutting of different types of straps, such as plastic, steel, or polyester straps. To ensure safe and effective operation, it's crucial to understand the proper usage of a pneumatic strap cutter. Here's a step - by - step guide.

2026-01-19

Electric Cable Tie Gun Operating Instructions

An electric cable tie gun is a handy tool that simplifies the process of securing cable ties, making it faster and more efficient compared to manual methods. Whether you're working on electrical installations, organizing cables in a data center, or bundling items for shipping, understanding how to properly use an electric cable tie gun is essential. Here's a detailed guide to help you get started.

2026-01-18

The precise tension control method for cable guns

When working with cable tie guns, achieving the right tension is crucial for ensuring secure and professional-looking installations. Whether you're bundling cables, securing equipment, or organizing items, precise tension control prevents over-tightening, which can damage delicate components, and under-tightening, which may lead to loosening over time. Here are some effective methods to help you master precise tension control with a cable tie gun.

2026-01-18

The technique for cutting plastic cable ties using diagonal pliers

Plastic cable ties are widely used for bundling and securing items, but cutting them cleanly and safely requires the right approach, especially when using diagonal cutting pliers. Here are some practical techniques to ensure efficient and precise cutting every time.