14

2025

-

12

The size of agricultural plastic cable ties is compatible

Author:

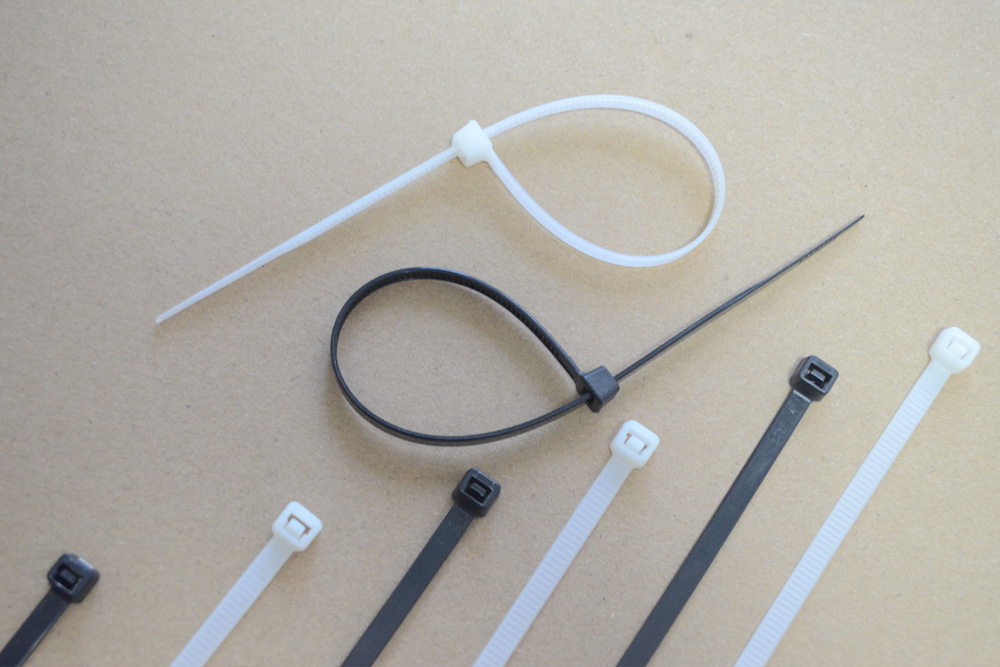

Dimensional Adaptability of Plastic Strapping for Agricultural Applications

Common Width and Length Combinations for Crop Bundling

Agricultural plastic strapping is designed to accommodate varying crop sizes and bundling requirements. For lightweight applications like bundling vegetable stems or herb stalks, narrow strapping widths of 3–4mm paired with lengths of 100–150mm provide sufficient strength without over-tightening. These dimensions prevent damage to delicate plant tissues while maintaining secure fastening during transportation or storage.

Medium-width strapping (5–6mm) with lengths of 200–300mm is ideal for bundling medium-sized crops such as corn stalks, wheat sheaves, or hay bales. The increased width distributes tension more evenly, reducing the risk of breakage under moderate loads. For larger agricultural products like sugar cane or tree trunks, strapping widths of 8–10mm and lengths exceeding 400mm ensure stability during handling and processing. These dimensions are particularly useful for securing heavy loads on pallets or in shipping containers.

Adjustable-length strapping systems with sliding buckles or self-locking mechanisms offer flexibility for irregularly shaped bundles. This adaptability is critical for agricultural waste management, where materials like vine prunings or crop residues vary in size and density. By eliminating the need for precise cutting, adjustable strapping reduces material waste and improves operational efficiency.

Environmental Adaptability for Field and Storage Use

Agricultural environments expose strapping to extreme conditions, requiring materials that resist degradation. UV-stabilized polypropylene (PP) strapping maintains mechanical properties under prolonged sunlight exposure, making it suitable for outdoor field applications. In regions with high humidity or frequent rainfall, moisture-resistant coatings prevent swelling or weakening, ensuring consistent performance during wet harvest seasons.

For cold-climate agriculture, low-temperature-resistant strapping (rated to -40°C) prevents embrittlement, reducing the risk of snap-breaking during winter bundling tasks. Conversely, in hot, arid regions, heat-resistant variants withstand temperatures exceeding 60°C without deformation, maintaining load security during summer storage. These environmental adaptations extend strapping lifespan, lowering replacement costs for farmers.

Biodegradable strapping options derived from plant-based polymers (e.g., PLA) address sustainability concerns in agriculture. These materials decompose naturally within 6–12 months, minimizing plastic waste in soil or composting systems. While their tensile strength is slightly lower than traditional plastics, they are sufficient for lightweight bundling tasks like securing seedling trays or mulch films.

Tensile Strength Requirements for Heavy-Duty Applications

Heavy agricultural machinery and large-scale crop processing demand strapping with high tensile strength. For bundling steel frames of harvesting equipment or securing heavy machinery parts during transport, strapping with minimum breaking loads of 500–800N is recommended. These dimensions (typically 10–12mm width) resist pulling forces from vibrations or impacts, preventing load shifting.

In silage or grain storage, strapping must withstand compression forces from stacked bales or sacks. High-tensile polyester (PET) strapping with elongation rates below 10% maintains tightness over time, reducing spoilage risks. For example, strapping used to secure 500kg silage bales requires a minimum tensile strength of 1,200N to prevent rupture during lifting or stacking.

Dynamic load applications, such as bundling livestock feed or fertilizer bags on moving conveyors, require strapping with shock-absorbing properties. Nylon-blend strapping with elasticity modules of 200–300MPa absorbs vibrations without loosening, ensuring consistent fastening during high-speed processing. This adaptability is critical for maintaining productivity in automated agricultural systems.

plastic cable ties

Previous Page

Hot News

2025-12-15

Plastic cable tie threading operation skills

Essential Techniques for Threading Plastic Cable Ties Efficiently Proper Hand Positioning and Grip Control Mastering hand placement is critical for smooth threading. Hold the cable tie head firmly between your thumb and index finger, keeping the tail end aligned with your workspace. For narrow ties (3–5mm width), use a pincer grip to maintain precision, while wider ties (8–12mm) require a full-hand grasp to distribute pressure evenly. Avoid bending the tail excessively, as this can create kinks that hinder threading. When working in tight spaces, rotate your wrist slightly to adjust the angle of the tie. This maneuver helps navigate corners or gaps without forcing the material, which could weaken its locking mechanism. For overhead applications, stabilize your elbow against a surface to reduce hand fatigue and improve accuracy. Grip strength matters during initial insertion. Apply moderate pressure to push the tail through the head’s locking gear, but avoid squeezing too hard, which may deform the plastic. If resistance occurs, wiggle the tail gently while maintaining forward momentum to ease it through the channel. Navigating Tight Spaces and Complex Configurations Threading cable ties through confined areas demands strategic planning. Start by assessing the path’s layout, identifying potential obstructions like wires, pipes, or structural components. For straight-line threading, align the tie’s tail with the intended route before inserting it into the head, minimizing mid-process adjustments. In multi-angle setups, such as bundling cables around a corner, use a staggered approach. Thread the tie partially through the first opening, then rotate the head to align with the next segment. This step-by-step method prevents the tail from binding against obstacles. For loops or circular patterns, create a small bend at the tail’s tip to guide it through the head more easily. When dealing with overlapping materials, like securing layers of insulation, separate the components slightly to create a clear threading path. Insert the tie between the layers at a 45-degree angle, then level it out as you pull it through. This technique reduces friction and ensures the tie sits flush against the surface. Managing Threading Resistance and Preventing Jams Resistance during threading often stems from misalignment or material deformation. If the tail gets stuck, avoid pulling backward, as this can worsen the jam. Instead, gently twist the head clockwise or counterclockwise while applying light forward pressure. The rotational motion helps realign the locking gear with the tail’s ridges. Lubrication can reduce friction in stubborn cases. Apply a small amount of silicone-based spray or dry lubricant to the tail’s surface, focusing on the area near the head. Avoid oil-based products, which may attract dust or degrade the plastic over time. After lubricating, wipe away excess residue to maintain a clean threading path. Preventative measures minimize jams before they occur. Inspect the head’s locking gear for debris or burrs that could obstruct the tail. Use a needle or thin tool to clear any blockages gently. Additionally, store cable ties in a dry, cool environment to prevent warping, which alters their dimensions and complicates threading. Optimizing Threading Speed for High-Volume Tasks Efficiency improves with practice and ergonomic adjustments. Develop a rhythm by threading multiple ties in sequence without pausing between each step. For repetitive tasks, position components within easy reach to reduce movement time. Use a tray or magnetic holder to organize ties by size, ensuring quick access during assembly. Pre-threading techniques save time in bulk applications. For example, when securing bundles of cables, lay the ties out in advance and thread them loosely around the group before tightening. This approach allows you to adjust positions quickly without rethreading each tie individually. Leverage tool-assisted methods for heavy-duty projects. Tensioning devices with built-in threading guides streamline the process by aligning the tail automatically as you pull. These tools are particularly useful for wide or high-tension ties, where manual threading requires significant effort.

2025-12-15

Standard strapping steps for plastic cable ties

Proper preparation ensures optimal performance and prevents damage during the bundling process. Begin by selecting strapping material suited to the load’s weight and environmental conditions. For lightweight items like cardboard boxes, narrow strapping (3–5mm width) is sufficient, while heavier loads such as machinery parts require wider strapping (8–12mm). Inspect the strapping for defects like cracks, uneven edges, or discoloration, which could compromise strength.

2025-12-14

The size of agricultural plastic cable ties is compatible

Agricultural plastic strapping is designed to accommodate varying crop sizes and bundling requirements. For lightweight applications like bundling vegetable stems or herb stalks, narrow strapping widths of 3–4mm paired with lengths of 100–150mm provide sufficient strength without over-tightening. These dimensions prevent damage to delicate plant tissues while maintaining secure fastening during transportation or storage.

2025-12-14

Specification requirements for plastic cable ties of medical devices

Medical-grade plastic strapping must comply with ISO 10993 standards for biocompatibility, ensuring no cellular toxicity, skin irritation, or allergic reactions. Polypropylene (PP) and polyethylene (PE) are commonly used due to their chemical inertness, which prevents degradation when exposed to disinfectants, bodily fluids, or pharmaceuticals. For high-temperature sterilization processes, polyphenylsulfone (PPSU) is preferred as it withstands 121°C without deformation, maintaining structural integrity for surgical instrument packaging.