04

2025

-

12

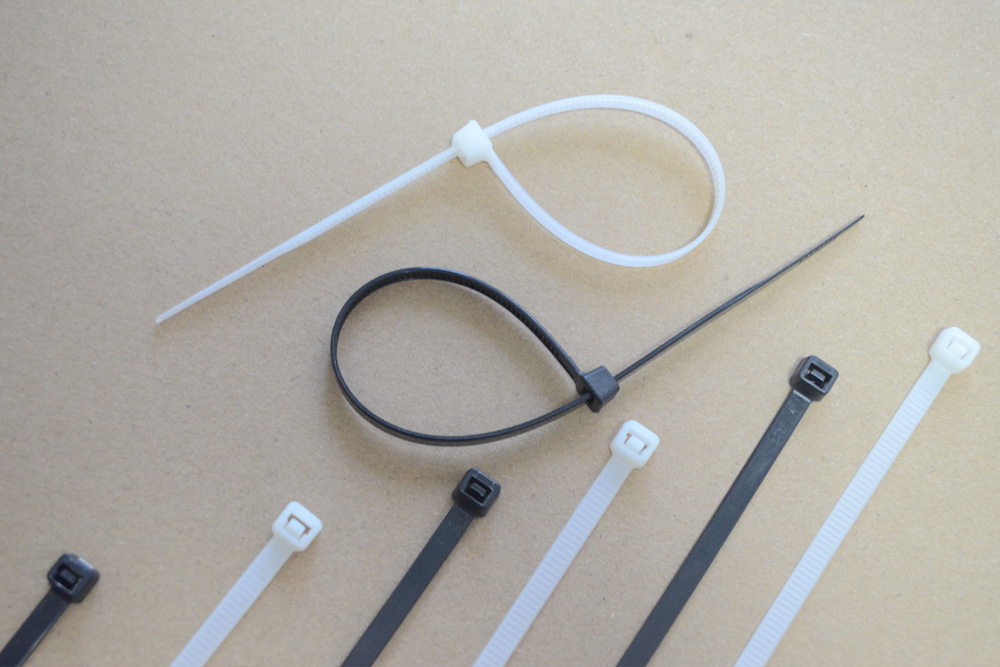

Selection of plastic cable ties for high-temperature operations

Author:

Selecting Plastic Cable Ties for High-Temperature Work Environments: A Comprehensive Guide

Understanding High-Temperature Requirements

High-temperature work environments, such as industrial machinery, automotive systems, and outdoor installations exposed to direct sunlight, demand cable ties that can withstand extreme thermal conditions. These ties must maintain structural integrity, tensile strength, and flexibility without degrading or becoming brittle. The operating temperature range for such applications typically spans from 120°C to 260°C, depending on the severity of the environment.

Critical Temperature Thresholds

- Short-Term Exposure: Some applications involve brief exposure to temperatures exceeding 200°C, such as during welding or engine operation. Ties used in these scenarios must resist melting or warping.

- Long-Term Stability: For continuous use in environments like boiler rooms or solar panel arrays, ties must endure prolonged exposure to temperatures between 120°C and 180°C without losing functionality.

- Thermal Cycling: Applications involving frequent temperature fluctuations, such as automotive engines or HVAC systems, require ties that resist cracking or loosening due to repeated expansion and contraction.

Material Selection for High-Temperature Resistance

The choice of material directly impacts a cable tie’s ability to perform in high-temperature settings. Common engineering plastics like polypropylene (PP) or standard nylon (PA6) are unsuitable for extreme heat, as they degrade rapidly above 85°C. Instead, specialized materials are required.

Advanced Engineering Plastics

- Polyamide 66 (PA66): A modified version of PA66, often referred to as "high-heat PA66," can withstand temperatures up to 150°C. This material is commonly used in automotive wiring harnesses and industrial equipment.

- Polyether Ether Ketone (PEEK): PEEK-based ties offer exceptional heat resistance, withstanding temperatures up to 260°C. They are ideal for aerospace, semiconductor manufacturing, and chemical processing applications where extreme conditions are routine.

- Polyphenylene Sulfide (PPS): PPS ties maintain stability up to 240°C and resist chemicals, making them suitable for automotive exhaust systems and electrical insulation in high-temperature zones.

Flame Retardancy and Safety Compliance

In addition to heat resistance, ties used in high-temperature environments must often meet flame retardancy standards, such as UL94 V-0 or V-2. These ratings ensure the ties do not propagate flames or emit toxic gases when exposed to fire, enhancing safety in critical applications like electrical enclosures or transportation systems.

Dimensional Specifications for High-Temperature Applications

The physical dimensions of a cable tie influence its load-bearing capacity and adaptability to bundled objects. In high-temperature settings, ties must accommodate thermal expansion while maintaining secure fastening.

Width and Thickness Considerations

- Light-Duty Ties (2.5–4mm wide): Suitable for bundling small cables or securing lightweight components in moderate-heat environments (up to 120°C). These ties are often used in automotive interior wiring or consumer electronics.

- Medium-Duty Ties (4.8–7.6mm wide): Designed for medium-sized bundles, such as hydraulic hoses or industrial piping, in temperatures up to 180°C. Their thickness (0.8–1.2mm) balances flexibility and strength.

- Heavy-Duty Ties (8.8mm and above): Used for anchoring large-diameter pipes, structural supports, or heavy machinery in extreme-heat environments (up to 260°C). These ties feature thicknesses exceeding 1.5mm to withstand high tensile loads.

Length Customization

- Standard Lengths (100–400mm): Common for general-purpose bundling in moderate-heat applications.

- Extended Lengths (500–1500mm): Required for securing long sections of cable or pipe in industrial installations, ensuring complete coverage without overlapping.

Performance Metrics for High-Temperature Reliability

Beyond material and dimensions, performance characteristics determine a tie’s suitability for high-temperature work. These metrics ensure ties remain functional under stress, vibration, and thermal cycling.

Tensile Strength and Load Capacity

- Minimum Tensile Strength: Light-duty ties typically withstand 8–18 kg of force, while heavy-duty variants exceed 50 kg. In high-temperature environments, ties must maintain these ratings even at elevated temperatures.

- Dynamic Load Handling: Ties used in vibrating machinery or wind-exposed structures should resist fatigue failure over extended periods.

Thermal Stability and Aging Resistance

- High-Temperature Aging Tests: Ties are subjected to accelerated aging tests, such as 1000 hours at 150°C or 4000 hours at 135°C, to ensure long-term performance without degradation.

- Thermal Shock Resistance: Ties must endure rapid temperature fluctuations without cracking or loosening, a critical feature for applications like automotive engines or outdoor solar installations.

Chemical and Environmental Resistance

- Chemical Stability: High-temperature environments often involve exposure to oils, solvents, or corrosive substances. Ties must resist chemical degradation to maintain functionality.

- UV Resistance: For outdoor applications, ties should incorporate UV stabilizers to prevent brittleness caused by prolonged sunlight exposure.

Application-Specific Considerations for High-Temperature Work

The intended use case dictates the selection of cable tie specifications. Different industries impose unique demands on ties, from automotive manufacturing to renewable energy infrastructure.

Automotive Applications

- Engine Compartments: Ties must withstand temperatures up to 180°C while securing wiring harnesses, fuel lines, and hydraulic hoses.

- Exhaust Systems: High-heat PPS or PEEK ties are used to anchor exhaust pipes, ensuring stability without melting or degrading.

Industrial and Manufacturing Uses

- Boiler Rooms and Furnaces: Ties must endure temperatures exceeding 200°C while securing insulation materials or piping systems.

- Chemical Processing: Flame-retardant ties resist chemical corrosion and high temperatures, ensuring safety in hazardous environments.

Renewable Energy Installations

- Solar Panel Arrays: Ties secure cables and mounting frames in rooftop or ground-mounted solar farms, withstanding prolonged exposure to sunlight and heat.

- Wind Turbines: Heavy-duty ties anchor cables and hydraulic hoses in turbine nacelles, where vibration and temperature extremes demand robust fastening solutions.

By aligning material properties, dimensional precision, and performance metrics with the demands of high-temperature work environments, users can select cable ties that deliver reliable, long-lasting performance in even the most challenging conditions.

plastic cable ties

Hot News

2025-12-08

Selection of plastic cable ties for gardening

The effectiveness of plastic cable ties in gardening hinges on matching their dimensions to the specific needs of plants. Length determines how much space the tie can cover, while width influences its load-bearing capacity. For instance, securing thin tomato stems to stakes requires shorter ties (100–150mm), whereas bundling multiple grapevine branches demands longer options (300–400mm). Width selection follows a similar logic: narrow ties (2–4mm) work for lightweight foliage, while wider variants (6–8mm) resist pulling forces from heavy fruits or wind exposure.

2025-12-08

Recommended specifications of plastic cable ties for home storage

When selecting plastic cable ties for home organization, material composition directly impacts durability and functionality. Nylon-based cable ties, engineered from polyamide (PA6 or PA66), offer superior resistance to temperature fluctuations (-40°C to 85°C) and physical stress. These ties maintain flexibility even after repeated bending, making them ideal for outdoor applications like securing garden hoses or bundling patio furniture.

2025-12-05

The specifications of plastic cable ties for vibration scenarios are compatible

When securing components in environments with constant or intermittent vibration, choosing the correct plastic cable tie specifications is critical to ensuring long-term reliability and safety. Vibration can cause standard cable ties to loosen, fatigue, or break over time, leading to equipment damage or operational disruptions. This guide explores key factors to consider when selecting cable ties for vibration-heavy settings, covering material properties, mechanical design, and installation techniques.

2025-12-05

Material selection for plastic cable ties in chemical environments

When selecting plastic cable ties for chemical environments, the choice of material directly impacts performance, durability, and safety. Different chemical agents—such as acids, alkalis, solvents, and salts—pose unique challenges, requiring materials with tailored resistance properties. This guide explores three primary material options for chemical-resistant cable ties, analyzing their strengths, limitations, and ideal applications.