13

2025

-

10

Tightening method of plastic cable ties

Author:

Effective Techniques for Tightening Plastic Cable Ties Securely

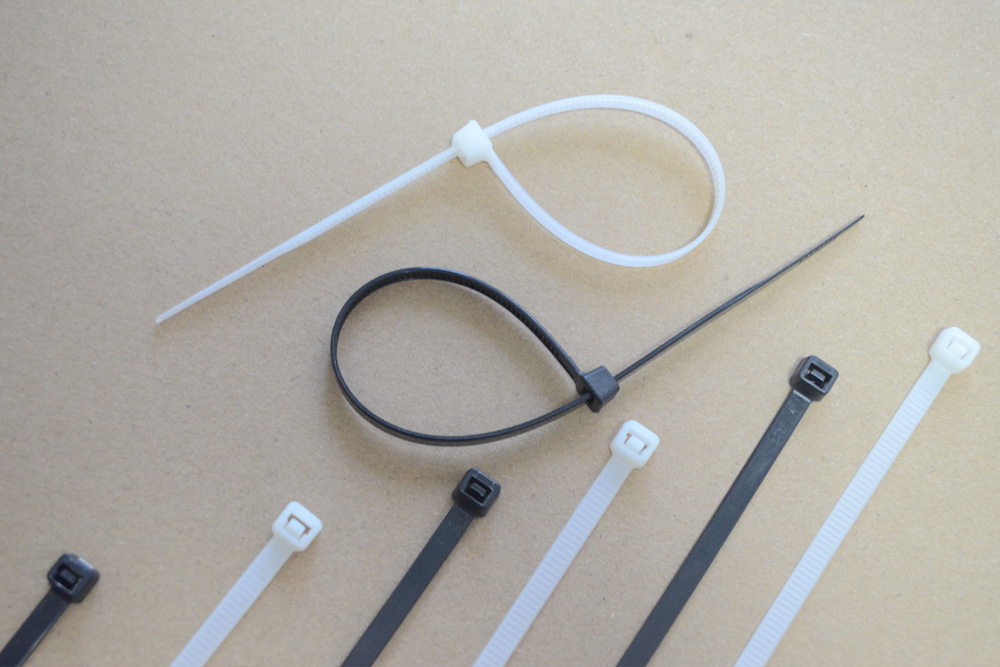

Plastic cable ties are essential for organizing wires, securing pipes, or bundling materials in various settings, from industrial workshops to home projects. Achieving the right tension is crucial—too loose, and the tie may slip; too tight, and it could damage the bundled items or the tie itself. Below, we explore step-by-step methods to tighten cable ties safely and effectively without compromising their integrity.

Preparing the Bundle Before Tightening

Proper preparation ensures the cable tie grips evenly and prevents uneven stress distribution:

- Align Items Evenly: Arrange cables, hoses, or pipes in a straight, parallel formation. Overlapping or twisted items create pressure points that may cause the tie to loosen over time. For example, when securing electrical wires, ensure they lie flat against each other without kinks.

- Estimate the Required Length: Before inserting the tie, loop it loosely around the bundle to gauge the correct length. A tie that is too short may struggle to close, while an excessively long tie could leave a loose tail prone to snagging. Leave enough slack to thread the tail through the locking head comfortably.

- Position for Accessibility: Place the bundle in a location where the tie’s locking head is easily reachable. Avoid tight spaces where fingers or tools cannot maneuver, as this may lead to over-tightening or improper locking.

By aligning items and estimating length, users reduce the need for adjustments after tightening, minimizing stress on the tie.

Inserting and Threading the Tie Correctly

The initial threading process sets the foundation for a secure fit:

- Thread the Tail Through the Locking Head: Insert the pointed end of the tie into the rectangular slot of the locking head. Ensure the tail passes smoothly without bending or kinking, as sharp angles can weaken the tie’s structure. For right-handed users, threading from left to right often provides better control.

- Maintain a Straight Path: Keep the tie aligned with the bundle as you thread it. Twisting or angling the tie during insertion can create internal stress, leading to cracks or breakage under tension.

- Check for Proper Alignment: Once threaded, verify that the tie lies flat against the bundle. Misalignment may cause the locking mechanism to engage unevenly, reducing the tie’s holding power.

Correct threading ensures the tie’s locking mechanism functions as intended, providing a stable base for tightening.

Applying Gradual Tension for Optimal Security

Tightening the tie requires patience and precision to balance grip and flexibility:

- Pull the Tail Steadily: Grasp the tail firmly and apply steady, incremental pressure to tighten the tie around the bundle. Avoid sudden jerks, which can cause uneven tension or stretch the locking mechanism. Instead, use a controlled motion to draw the tie snug.

- Monitor the Bundle’s Response: As you tighten, observe how the bundled items react. If cables begin to bend or pipes shift, pause and adjust the alignment. Over-tightening can deform soft materials or compress insulation on wires, leading to long-term damage.

- Engage the Locking Mechanism: Once the desired tension is achieved, press the tail firmly into the locking head. The serrated teeth should interlock with the pawl (the small protrusion inside the head) without slipping. Listen for a distinct “click” to confirm engagement. If the tie loosens when tugged lightly, repeat the tightening process.

Gradual tensioning prevents over-compression and ensures the tie holds securely without damaging the bundle.

Adjusting Tension for Dynamic or Sensitive Applications

Some scenarios require flexibility, such as when bundled items may expand, contract, or shift over time:

- Loosening Without Damage: If the tie is too tight, insert a flathead screwdriver or similar tool into the locking head’s pawl. Gently lift the pawl to release tension, then re-tighten to the desired level. Avoid forcing the tool, as this could damage the locking mechanism.

- Using Reusable Ties for Frequent Adjustments: For applications needing regular tightening or loosening, consider ties designed with a reusable locking head. These allow for multiple adjustments without degrading the material. While standard ties are single-use, reusable options are ideal for temporary setups or prototypes.

- Accounting for Environmental Factors: Temperature changes or chemical exposure can affect the tie’s elasticity. In high-heat environments, such as engine compartments, the tie may expand slightly. Conversely, cold temperatures can make it brittle. Adjust tension periodically to account for these fluctuations.

Dynamic adjustments ensure the tie adapts to changing conditions without failing prematurely.

Avoiding Common Mistakes That Compromise Tightness

Even experienced users can make errors that reduce the tie’s effectiveness:

- Over-Tightening Beyond Capacity: Applying excessive force can stretch the locking mechanism or crack the tie. Aim for a snug fit that allows slight movement without slippage. If the tie feels rigid or the bundle shows signs of stress, loosen it slightly.

- Reusing Single-Use Ties: Standard cable ties are designed for one-time use. Attempting to reopen and reuse them weakens the locking mechanism, increasing the risk of failure. Discard used ties and replace them with new ones for critical applications.

- Ignoring Material Limitations: Different ties are engineered for specific environments. Using a standard nylon tie in a high-temperature setting, for example, may cause it to melt or deform. Always match the tie’s material properties to the application’s demands.

By avoiding these pitfalls, users can maximize the tie’s lifespan and performance while maintaining a secure hold.

plastic cable ties

Next Page

Hot News

2025-10-13

Tightening method of plastic cable ties

Plastic cable ties are essential for organizing wires, securing pipes, or bundling materials in various settings, from industrial workshops to home projects. Achieving the right tension is crucial—too loose, and the tie may slip; too tight, and it could damage the bundled items or the tie itself. Below, we explore step-by-step methods to tighten cable ties safely and effectively without compromising their integrity.

2025-10-13

Plastic cable tie cutting techniques

Plastic cable ties are indispensable for organizing wires, securing pipes, or bundling materials in industrial, automotive, and household settings. However, improper cutting techniques can leave sharp edges, damage surrounding components, or compromise the tie’s structural integrity. Below, we explore step-by-step methods to achieve clean, safe cuts without compromising functionality.

2025-10-12

The correct binding method for plastic cable ties

Plastic cable ties are widely used across industries for bundling wires, securing pipes, or organizing components. When applied correctly, they provide reliable, long-lasting support. However, improper绑扎 (tying) methods can lead to loosening, breakage, or uneven stress distribution. Below, we explore step-by-step techniques to ensure optimal performance without compromising structural integrity.

2025-10-12

Non-deformable plastic cable tie design

Plastic cable ties are essential for securing cables, pipes, and components in industries ranging from construction to automotive manufacturing. However, deformation under tension, temperature fluctuations, or repeated use can compromise their effectiveness. By focusing on material selection, structural engineering, and locking mechanisms, designers can create ties that maintain their shape and strength over time. Below, we explore the key strategies for achieving minimal deformation.