12

2025

-

10

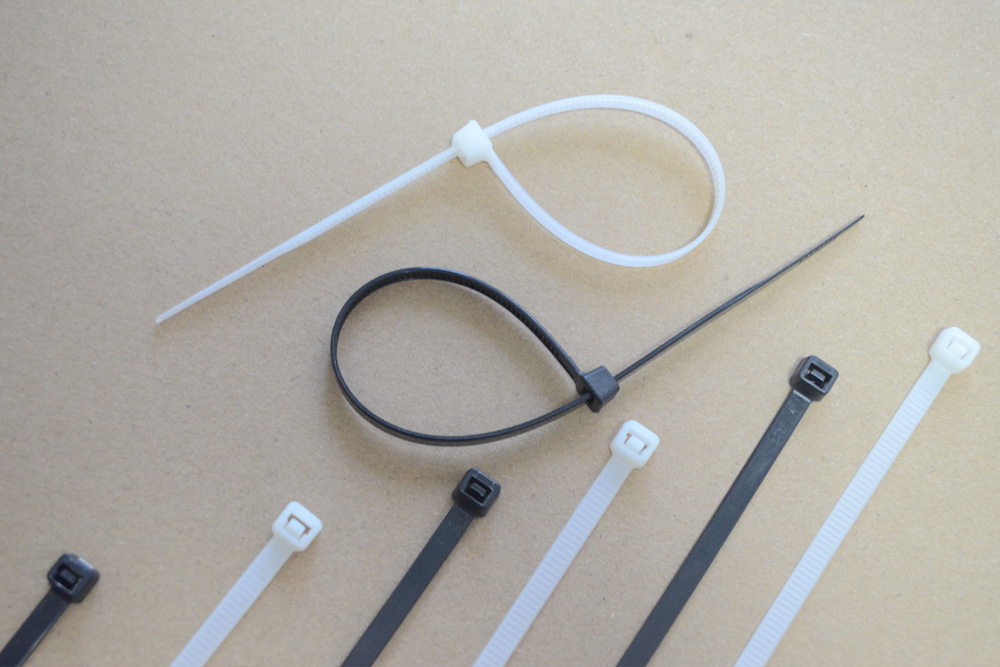

Non-deformable plastic cable tie design

Author:

Design Principles for Plastic Cable Ties with Minimal Deformation

Plastic cable ties are essential for securing cables, pipes, and components in industries ranging from construction to automotive manufacturing. However, deformation under tension, temperature fluctuations, or repeated use can compromise their effectiveness. By focusing on material selection, structural engineering, and locking mechanisms, designers can create ties that maintain their shape and strength over time. Below, we explore the key strategies for achieving minimal deformation.

Structural Reinforcement Through Ribbing and Thickness Optimization

The physical structure of a cable tie plays a critical role in its resistance to bending and stretching. Thoughtful design modifications can significantly enhance durability:

- Longitudinal Ribbing: Adding raised ribs along the length of the tie distributes stress more evenly, preventing localized deformation. These ribs act as stiffeners, reducing the likelihood of the tie bowing under tension. For example, a tie with parallel ribs can withstand higher pulling forces without elongating compared to a flat design.

- Variable Thickness Profiles: Tapering the tie’s thickness from the head to the tail allows for flexibility at the insertion point while maintaining rigidity near the locking mechanism. This design ensures the tail can bend slightly during insertion but resists stretching once locked.

- Curved or Contoured Shapes: Some applications benefit from ties with a slight curve or ergonomic shape that aligns with the bundled items. A curved tie, for instance, conforms better to cylindrical objects like pipes, reducing stress concentrations that could lead to deformation.

These structural enhancements minimize deformation by optimizing how forces are transmitted through the tie’s body.

Advanced Locking Mechanisms for Secure Tension Control

The locking mechanism is the primary point of failure for many cable ties, as repeated tightening or loosening can wear down the teeth or pawl. Innovations in locking design address these issues:

- Dual-Pawl Systems: Traditional ties rely on a single pawl engaging with serrated teeth. Dual-pawl designs distribute the load across two points, reducing wear and preventing slippage. This is particularly effective in high-vibration environments, such as automotive assemblies, where constant movement could loosen a single-pawl tie.

- Adjustable Tension Locks: Some ties incorporate a sliding or ratcheting mechanism that allows users to set a specific tension level. Once locked, the mechanism prevents over-tightening, which can cause permanent deformation. This feature is valuable in delicate applications, like securing fiber-optic cables, where excessive force could damage the contents.

- Self-Locking with Memory: Certain materials, such as reinforced nylon, can be engineered to “remember” their original shape. When paired with a self-locking head, the tie returns to its preset form after minor deformations, ensuring consistent performance over time.

By refining the locking mechanism, designers can create ties that maintain tension without compromising structural integrity.

Material Engineering for Temperature and Chemical Resistance

Environmental factors, including temperature extremes and chemical exposure, can cause plastic ties to soften, crack, or warp. Selecting and modifying materials addresses these challenges:

- High-Temperature Polymers: Polymers like polyether ether ketone (PEEK) or polyphenylene sulfide (PPS) retain their stiffness at temperatures exceeding 200°C. These materials are ideal for automotive engine compartments or industrial machinery where standard nylon would deform.

- Chemical-Resistant Additives: Incorporating stabilizers and fillers into the polymer matrix enhances resistance to solvents, oils, and acids. For example, a tie used in a chemical plant might include fluoropolymer additives to prevent swelling or degradation when exposed to harsh substances.

- Cryogenic Compatibility: In low-temperature applications, such as cryogenic storage or aerospace, materials like polyimide or modified nylon maintain flexibility and strength at sub-zero temperatures. This prevents brittleness and cracking that could lead to deformation.

Material engineering ensures ties perform reliably across a wide range of environmental conditions without permanent shape changes.

Ergonomic Design for Reduced User-Induced Stress

While material and structural choices are critical, ergonomic design can also influence deformation. Ties that are difficult to handle may be over-tightened or mishandled, leading to unnecessary stress:

- Wide, Textured Heads: A larger head with grip-enhancing textures allows users to apply force evenly during insertion and tightening. This reduces the likelihood of twisting or bending the tie, which could cause uneven stress distribution.

- Pre-Curved Tails: Some ties are manufactured with a slight curve in the tail, guiding it toward the locking mechanism more naturally. This reduces the need for excessive bending during use, minimizing the risk of kinking or permanent deformation.

- Color-Coded Tension Indicators: Ties with visual markers, such as color bands or printed guidelines, help users apply the correct tension. Over-tightening is a common cause of deformation, and these indicators promote consistent, safe usage.

Ergonomic improvements lower the risk of user error, ensuring ties are used in a way that preserves their structural integrity.

Long-Term Performance Through Aging Resistance

Even in ideal conditions, plastic materials can degrade over time due to oxidation, hydrolysis, or light exposure. Designing for long-term performance involves:

- Antioxidant Additives: These chemicals slow down the breakdown of polymer chains caused by oxygen exposure, extending the tie’s usable life.

- Hydrolysis-Resistant Formulations: For humid or wet environments, materials like polyamide 12 (PA12) are modified to resist water absorption, which can soften the plastic and lead to deformation.

- Light-Stabilizing Coatings: Clear or pigmented coatings can be applied to the tie’s surface to block UV rays, preventing the polymer from becoming brittle or discolored over time.

By addressing aging mechanisms, designers ensure ties retain their shape and strength throughout their intended lifespan.

plastic cable ties

Previous Page

Next Page

Previous Page

Next Page

Hot News

2025-10-12

The correct binding method for plastic cable ties

Plastic cable ties are widely used across industries for bundling wires, securing pipes, or organizing components. When applied correctly, they provide reliable, long-lasting support. However, improper绑扎 (tying) methods can lead to loosening, breakage, or uneven stress distribution. Below, we explore step-by-step techniques to ensure optimal performance without compromising structural integrity.

2025-10-12

Non-deformable plastic cable tie design

Plastic cable ties are essential for securing cables, pipes, and components in industries ranging from construction to automotive manufacturing. However, deformation under tension, temperature fluctuations, or repeated use can compromise their effectiveness. By focusing on material selection, structural engineering, and locking mechanisms, designers can create ties that maintain their shape and strength over time. Below, we explore the key strategies for achieving minimal deformation.

2025-10-12

Non-fading plastic cable tie material

Plastic cable ties are indispensable for bundling, securing, and organizing items across industries. When longevity and color retention are critical, selecting the right material ensures performance under prolonged exposure to sunlight, chemicals, or environmental stressors.

2025-10-10

Advantages of customizable plastic cable ties

Customizable plastic cable ties have become a cornerstone in industries requiring precision, efficiency, and brand differentiation. Unlike standard off-the-shelf options, these ties offer flexibility in design, material, and functionality, enabling businesses to address unique challenges. Below, we explore the key benefits of opting for customizable solutions.