06

2025

-

08

Key points for using plastic cable ties in underwater environments

Author:

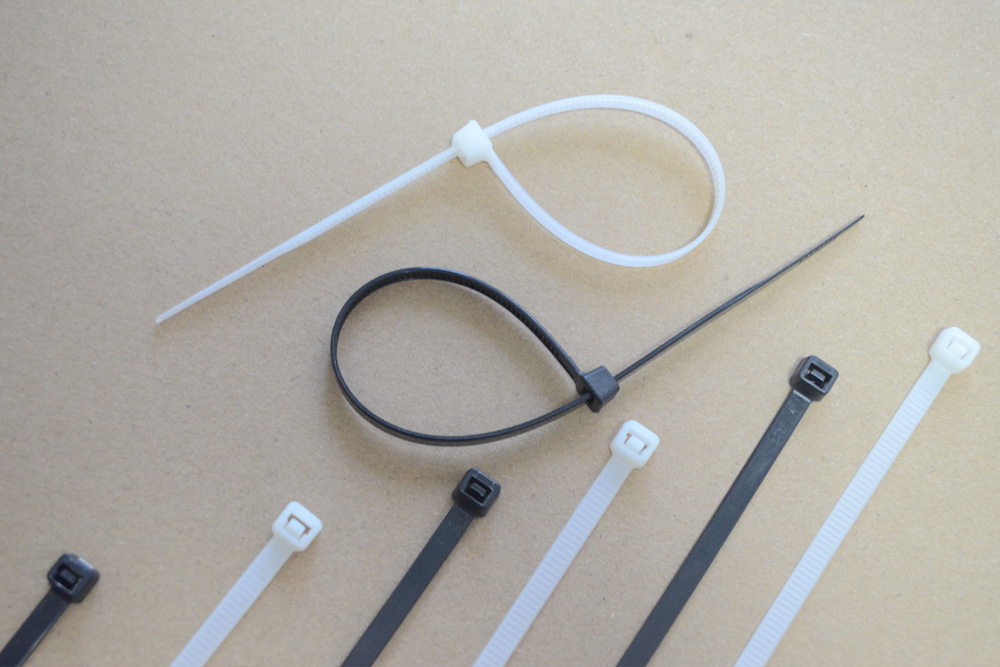

Key Considerations for Using Plastic Cable Ties in Underwater Environments: Durability, Installation, and Long-Term Performance

Underwater applications, such as marine engineering, aquaculture, or submerged infrastructure maintenance, demand materials and methods that withstand constant exposure to water, pressure, and potential chemical interactions. Plastic cable ties, when selected and used correctly, can provide reliable fastening in these environments, but their performance hinges on addressing factors like material degradation, installation challenges, and maintenance accessibility.

1. Selecting Water-Resistant Materials for Submerged Use

Not all plastic cable ties are engineered to endure prolonged underwater exposure. Choosing the right material composition is critical to prevent premature failure due to hydrolysis, UV degradation, or chemical corrosion.

- Opt for Nylon 6/6 or Polyamide Blends

Standard nylon ties may absorb water over time, leading to swelling, reduced tensile strength, or brittleness. Nylon 6/6, a common variant, offers better water resistance and maintains structural integrity under pressure. For instance, when securing underwater sensors or pipeline markers, nylon 6/6 ties resist degradation from saltwater or freshwater immersion. - Avoid PVC or Low-Grade Polymers

PVC ties can become brittle in cold water or degrade when exposed to certain chemicals, such as chlorine in swimming pools. Similarly, low-grade polymers may crack under hydrostatic pressure, compromising the fastening of components like aquarium filters or dockside equipment. - Consider UV Stabilization for Shallow Depths

In clear, shallow water where sunlight penetrates, UV rays can accelerate material breakdown. UV-stabilized ties, though primarily designed for outdoor use, provide an added layer of protection in sunlit underwater zones, such as reservoirs or coastal installations.

These material choices are essential for offshore oil platforms, fish farming cages, or underwater archaeological projects, where tie failure could lead to equipment loss or safety hazards.

2. Adapting Installation Techniques for Submerged Conditions

Underwater installation introduces challenges like reduced visibility, buoyancy effects, and the need for tools that function effectively in wet environments. Modifying traditional methods ensures ties are secured tightly and remain accessible for future adjustments.

- Use Pre-Cut Ties to Minimize On-Site Handling

Cutting ties underwater is impractical due to water resistance and the risk of losing small fragments. Pre-measure and trim ties to the required length before submersion, then thread them through components while dry. This approach is effective for assembling underwater lighting systems or securing cables in submerged data centers. - Employ Tools with Non-Slip Grips

Standard pliers or cutters may slip in wet hands, increasing the risk of dropping tools or applying uneven pressure. Choose tools with rubberized handles or textured surfaces to improve grip. For example, when tightening ties around coral reef monitoring equipment, non-slip pliers ensure precise tensioning without damaging delicate structures. - Anchor Ties to Fixed Points Before Tightening

In moving water, such as rivers or tidal zones, components can shift during installation, causing ties to loosen. Loop the tie loosely around the target object and a stable anchor point (e.g., a rock or concrete pillar) before pulling it tight. This method prevents misalignment in applications like securing buoys or underwater pipelines.

These techniques are vital for underwater construction, scientific research expeditions, or recreational diving projects, where efficiency and reliability underwater directly impact success.

3. Managing Maintenance and Inspection Challenges

Underwater ties require periodic checks to ensure they remain secure, especially in dynamic environments with fluctuating water levels, temperature changes, or biological growth. Planning for accessibility and corrosion resistance simplifies long-term upkeep.

- Schedule Regular Dive Inspections for Critical Components

Ties securing safety-critical equipment, such as emergency shut-off valves on submerged pipelines, should be inspected annually or after extreme weather events. Divers can visually assess ties for signs of swelling, cracking, or loosening and replace them as needed. - Prevent Biofouling with Anti-Microbial Coatings

In nutrient-rich water, algae, barnacles, or mussels can grow on ties, masking damage or adding weight that strains the fastening. Anti-microbial coatings, applied during manufacturing or as a post-installation spray, inhibit biological growth without harming aquatic life. This is useful for securing aquaculture nets or underwater observation cameras. - Design for Tool-Free Removal in High-Turnover Areas

In environments where ties are frequently replaced, such as temporary research stations or event installations, use ties with a built-in release tab or a looped design that allows easy cutting with blunt-nosed scissors. This reduces the need for specialized tools and minimizes downtime during maintenance.

These practices are indispensable for marine renewable energy projects, underwater cultural heritage preservation, or coastal erosion control systems, where long-term performance underwater is non-negotiable.

Optimizing Ties for Specific Underwater Challenges

- Mitigate Pressure Effects at Depth: In deep-water applications, such as securing submersible ROVs, choose ties with a high tensile strength-to-thickness ratio to withstand hydrostatic pressure without deforming. Test ties under simulated pressure conditions before deployment to ensure reliability.

- Address Chemical Exposure in Industrial Settings: Ties used in wastewater treatment plants or chemical storage facilities may contact corrosive substances like chlorine or acids. Select ties rated for chemical resistance or encapsulate them in a protective sleeve to extend their lifespan.

- Reduce Noise from Vibrating Ties: In underwater acoustic research or sensitive marine habitats, vibrating ties on equipment can generate unwanted noise. Dampen vibrations by wrapping ties in a layer of silicone or neoprene before tightening, ensuring minimal disruption to the environment.

By prioritizing material durability, adapting installation methods to underwater conditions, and planning for maintenance accessibility, plastic cable ties can serve as a dependable fastening solution in even the most demanding aquatic environments. These strategies ensure projects remain secure, functional, and environmentally responsible over time.

plastic cable ties

Previous Page

Hot News

2025-08-07

Plastic cable ties for interior decoration binding

Indoor decor projects often require creative solutions for bundling, securing, or organizing items without compromising style. Plastic cable ties, when used thoughtfully, can serve as versatile tools for everything from managing electrical cords to crafting decorative displays. Their strength, affordability, and ease of use make them ideal for DIY enthusiasts and professional decorators alike, provided they are applied in ways that align with aesthetic goals and structural needs.

2025-08-07

Plastic cable ties for outdoor use protection

Outdoor applications, ranging from construction projects and landscaping to vehicle maintenance and agricultural setups, expose plastic cable ties to harsh conditions that can degrade their performance over time. Factors like ultraviolet (UV) radiation, temperature fluctuations, moisture, and physical abrasion can weaken ties, leading to premature failure. Implementing targeted protection measures ensures their reliability and extends their lifespan in outdoor settings.

2025-08-06

Key points for using plastic cable ties in underwater environments

Underwater applications, such as marine engineering, aquaculture, or submerged infrastructure maintenance, demand materials and methods that withstand constant exposure to water, pressure, and potential chemical interactions. Plastic cable ties, when selected and used correctly, can provide reliable fastening in these environments, but their performance hinges on addressing factors like material degradation, installation challenges, and maintenance accessibility.

2025-08-06

The usage method of plastic cable ties for high-altitude operations

High-altitude tasks demand tools and methods that prioritize safety, stability, and efficiency. Plastic cable ties, when used correctly, can secure equipment, cables, or materials in elevated environments where traditional fasteners may be impractical. However, their application requires careful planning to address challenges like wind, limited access, and the need for one-handed operation. These guidelines ensure reliable performance while minimizing risks during aerial work.