05

2025

-

08

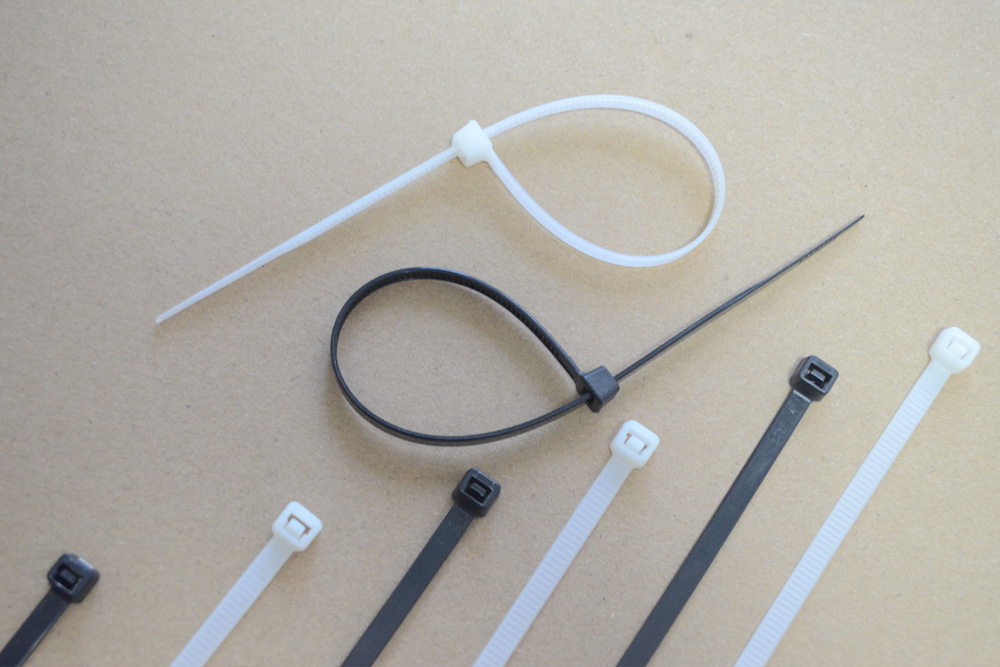

Plastic cable ties are used in confined Spaces

Author:

Maximizing Plastic Cable Ties in Tight Spaces: Techniques for Precision and Efficiency

Plastic cable ties are indispensable for securing components, but their effectiveness can be limited in confined areas where maneuverability is restricted. By adapting application methods and leveraging the material’s flexibility, users can overcome challenges like limited access, awkward angles, and the need for minimal clearance. These strategies ensure reliable fastening even in the most restrictive environments.

1. Selecting and Modifying Ties for Confined Areas

Not all cable ties are equally suited for tight spaces. Choosing the right type and adjusting its design can simplify installation and improve results in cramped conditions.

- Choose Low-Profile or Thin Ties

Opt for cable ties with a narrow width or reduced head size to minimize obstruction. Thinner ties slide more easily between components, while compact heads fit into narrower gaps. For example, when securing wires behind a dashboard, a slim tie prevents interference with adjacent controls. - Trim Excess Length Before Installation

Long tails on cable ties can snag on surrounding parts or block access to other fasteners. Measure the required length beforehand and trim the tail to a stubby 1–2 cm. This reduces bulk and ensures a cleaner finish in areas like engine compartments or electronic enclosures. - Use Pre-Formed or Angled Ties

If standard ties are too rigid, gently bend the head or tail at a 90-degree angle to align with the fastening path. This adaptation helps navigate corners or parallel surfaces without forcing the tie into an unnatural position. For instance, angle the head to follow the contour of a curved chassis when securing hoses.

These adjustments are critical in automotive repairs, server rack organization, or assembling compact electronic devices where space is at a premium.

2. Leveraging Tools and Accessories for Enhanced Control

Specialized tools and makeshift aids can compensate for the lack of manual dexterity in tight spaces, ensuring precise tensioning and cutting without damaging surrounding components.

- Employ Long-Reach Pliers or Cutters

Standard pliers may not fit into narrow gaps, but long-nosed or needle-nose variants provide the reach needed to grip and tighten ties in deep recesses. Similarly, flush-cutting pliers with extended handles allow trimming tails without disassembling the assembly. Use these tools when securing cables inside walls or behind appliances. - Use a Tensioning Tool for Consistent Results

Manual tightening can lead to over- or under-tensioning, especially when fingers can’t apply even pressure. A basic tensioning tool, which fits over the tie’s head, ensures uniform force distribution. This is useful in industrial settings where multiple ties must be installed identically, such as in control panels or machinery housings. - Create a Guide with Stiff Wire or Fishing Line

For ties that need to follow a specific path through multiple components, thread a stiff wire or fishing line through the intended route first. Attach the tie to the wire, then pull it into place. This method is effective in complex wiring harnesses or plumbing installations where visibility is limited.

These techniques are invaluable in aerospace maintenance, robotics assembly, or retrofitting systems in existing structures without major modifications.

3. Adopting Alternative Installation Methods for Challenging Angles

When traditional looping and tightening aren’t feasible, creative approaches like reverse wrapping, threading through pre-drilled holes, or using adjacent components as anchors can achieve secure fastening in unconventional ways.

- Reverse Wrap for Parallel Surfaces

Instead of looping the tie around an object, thread it backward through a gap between two parallel surfaces (e.g., between a circuit board and its casing). Pull the tail tight to clamp the components together. This method works well for securing heat sinks or mounting brackets in laptops or IoT devices. - Thread Ties Through Pre-Drilled Holes

In metal or plastic enclosures, drill small holes near the edges of components to be secured. Pass the tie through these holes and tighten it on the opposite side. This eliminates the need to maneuver around the object entirely and is ideal for fastening sensors or connectors in automotive ECU housings. - Use Adjacent Components as Anchors

When there’s no room to loop a tie around the target object, anchor it to a nearby fixed part. For example, secure a bundle of wires to a structural beam using a tie threaded through a pre-existing hole or wrapped around a protruding bolt. This approach is common in shipbuilding or large-scale machinery where components are densely packed.

These strategies are essential in medical device manufacturing, automotive subassembly, or any scenario where components must be immobilized without disrupting neighboring systems.

Optimizing Ties for Specific Tight-Space Challenges

- Prevent Snagging on Sharp Edges: In areas with exposed metal or plastic edges, wrap a layer of electrical tape around the tie’s head or tail to create a smooth surface. This reduces the risk of the tie catching during installation or removal.

- Manage Heat Sensitivity: In high-temperature environments like engine bays, use cable ties rated for elevated temperatures to avoid melting or deformation. Similarly, in cryogenic applications, choose ties that remain flexible at low temperatures.

- Reduce Visibility in Aesthetic Applications: For visible installations where the tie’s head must be hidden, route it behind a component or use a tie with a matte finish to minimize reflections. In consumer electronics, this ensures a polished appearance without compromising functionality.

By tailoring the choice of cable ties, utilizing specialized tools, and adopting unconventional installation methods, users can achieve secure and reliable fastening even in the most cramped spaces. These techniques expand the versatility of plastic cable ties, making them indispensable for projects where precision and adaptability are paramount.

plastic cable ties

Hot News

2025-08-05

Plastic cable ties are used in confined Spaces

Plastic cable ties are indispensable for securing components, but their effectiveness can be limited in confined areas where maneuverability is restricted. By adapting application methods and leveraging the material’s flexibility, users can overcome challenges like limited access, awkward angles, and the need for minimal clearance. These strategies ensure reliable fastening even in the most restrictive environments.

2025-08-05

Plastic cable ties are combined with ropes for binding

Plastic cable ties and rope each have distinct advantages: cable ties offer quick, permanent tension, while rope provides flexibility, adjustability, and strength under heavy loads. When used together, these materials create binding solutions that are secure, adaptable, and suitable for a wide range of applications, from outdoor repairs to industrial projects. Understanding how to integrate their strengths ensures reliable results in challenging scenarios.

2025-08-04

Plastic cable ties are used in combination with adhesive tape

Plastic cable ties and adhesive tape are versatile tools often used independently, but pairing them strategically can address challenges like securing irregular shapes, preventing slippage, or adding temporary flexibility to permanent fastenings. By understanding how these materials complement each other, users can create durable, adaptable solutions for projects ranging from household repairs to industrial installations.

2025-08-04

Plastic cable ties are used differently by color

Plastic cable ties are available in a variety of colors, offering more than just aesthetic appeal. By leveraging color distinctions, users can improve organization, safety, and efficiency in projects ranging from simple household tasks to complex industrial setups. Understanding how to assign colors based on purpose, environment, or workflow ensures clarity and reduces errors during installation and maintenance.