08

2025

-

10

Surface treatment of anti-slip plastic cable ties

Author:

Enhancing Grip and Safety: Surface Treatments for Non-Slip Plastic Zip Ties

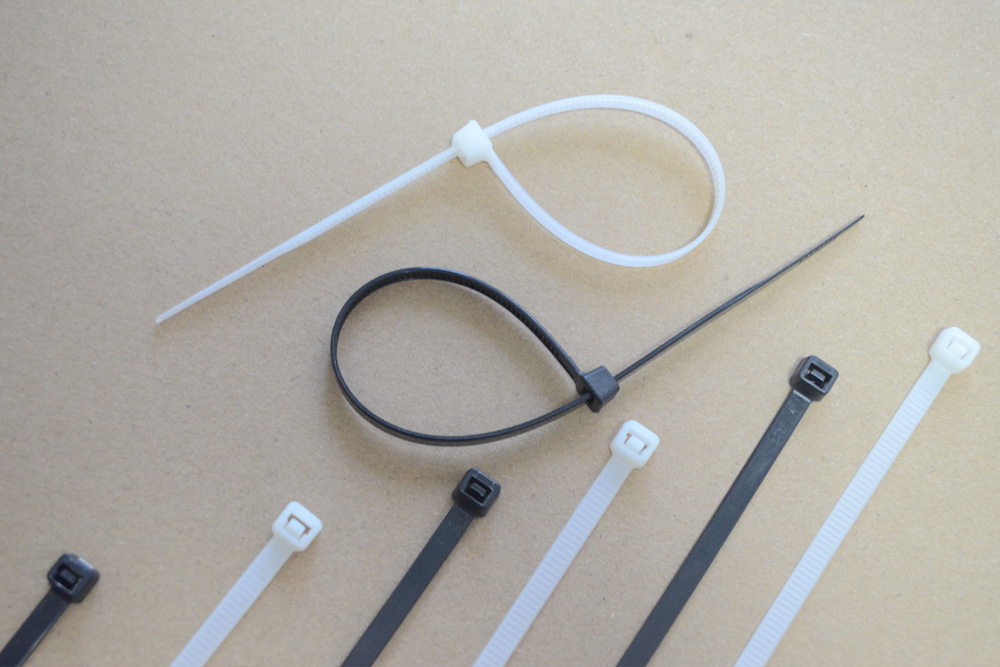

Plastic zip ties are essential for securing items, but their smooth surfaces can sometimes lead to slippage, especially under tension or in wet conditions. This compromises both functionality and safety, particularly in applications like construction, automotive repairs, or outdoor installations. By applying specialized surface treatments, manufacturers can significantly improve the grip and durability of zip ties, ensuring they stay firmly in place even in challenging environments. Below are innovative methods to enhance the non-slip properties of plastic zip ties through surface modifications.

Textured Surface Patterns for Improved Friction

One of the most straightforward ways to boost grip is by adding texture to the zip tie’s surface. This can be achieved through embossing or engraving fine patterns during the manufacturing process. For example, a series of parallel ridges or crosshatched lines along the strap increases the contact area with the secured object, creating more friction and reducing the likelihood of slippage. These textures are particularly effective when bundling cables or hoses, as they prevent the zip tie from rotating or sliding along the surface of the items it holds.

Another textured design involves creating small, raised bumps or nodules across the strap. These protrusions dig slightly into softer materials, such as rubber insulation on wires or foam packaging, providing additional anchoring. In industrial settings where zip ties are used to secure components on vibrating machinery, such textured surfaces help maintain stability by resisting movement caused by constant motion. The key is to balance the texture’s aggressiveness—too rough a pattern could damage delicate surfaces, while too smooth a design may not offer enough grip.

For applications requiring a high degree of precision, laser etching can create micro-textures that are invisible to the naked eye but highly effective at increasing friction. This method allows for intricate patterns tailored to specific use cases, such as anti-slip zones near the locking mechanism where slippage is most likely to occur. Laser-etched zip ties are often used in medical equipment assembly or aerospace manufacturing, where even minor movements could affect performance or safety.

Chemical Coatings to Enhance Traction and Durability

Applying specialized chemical coatings is another effective way to improve the non-slip properties of plastic zip ties. One common approach is using silicone-based coatings, which create a soft, tacky layer on the surface. This coating increases adhesion without leaving residue on the secured objects, making it ideal for temporary installations or scenarios where the zip tie may need to be removed and reused. Silicone coatings also resist moisture, preventing the grip from weakening in humid or wet conditions, such as outdoor electrical work or marine applications.

Another option is polyurethane (PU) coatings, which offer a balance of flexibility and abrasion resistance. PU-coated zip ties maintain their grip over time, even when exposed to repeated friction or environmental stressors like UV radiation or chemicals. These coatings are particularly useful in automotive manufacturing, where zip ties secure wiring harnesses near engine components that generate heat and vibrations. The PU layer acts as a protective barrier, ensuring the zip tie stays firmly in place without degrading.

For extreme environments, epoxy-based coatings provide maximum durability and traction. These coatings form a hard, glossy finish that resists scratches and wear, making them suitable for industrial settings where zip ties are subjected to heavy use. Epoxy coatings can also be formulated with anti-static properties, reducing the risk of sparks in environments with flammable materials, such as oil refineries or chemical plants. By combining grip enhancement with protective features, epoxy-coated zip ties offer a versatile solution for high-stakes applications.

Hybrid Approaches Combining Texture and Coatings

To achieve optimal non-slip performance, some manufacturers combine physical texturing with chemical coatings. For instance, a zip tie with embossed ridges can be coated with a thin layer of silicone, amplifying the effects of both treatments. The ridges provide initial traction, while the silicone coating fills in gaps and creates a uniform adhesive surface. This hybrid approach is especially effective in dynamic environments, such as fitness equipment assembly or amusement park rides, where zip ties must endure constant movement and varying loads.

Another hybrid method involves applying a textured base layer followed by a PU coating. The texture ensures immediate grip upon installation, while the PU layer enhances long-term durability and resistance to environmental factors. This combination is popular in outdoor construction projects, where zip ties secure scaffolding or temporary fencing. The dual treatment ensures the zip ties remain secure despite exposure to rain, wind, or temperature fluctuations, reducing the need for frequent replacements.

In scenarios requiring both grip and electrical insulation, a textured zip tie can be coated with a dielectric material like polyvinylidene fluoride (PVDF). PVDF coatings provide excellent electrical resistance while also improving traction, making them ideal for securing cables in data centers or power distribution systems. The texture prevents the zip tie from sliding along the cable, while the coating ensures safe operation by preventing short circuits or electrical interference.

Optimizing Zip Tie Performance Through Advanced Surface Treatments

Improving the non-slip properties of plastic zip ties involves a combination of physical texturing and chemical coatings tailored to specific applications. By adding ridges, bumps, or micro-patterns, manufacturers can increase friction and prevent slippage, while coatings like silicone, PU, or epoxy enhance durability and resistance to environmental factors. Hybrid approaches that combine these methods offer the best of both worlds, ensuring zip ties stay securely in place even under the most demanding conditions. Whether used in construction, automotive, or electronics, non-slip surface treatments make plastic zip ties more reliable and safer for a wide range of industries.

plastic cable ties

Previous Page

Previous Page

Hot News

2025-10-08

Application scenarios of waterproof plastic cable ties

Waterproof plastic zip ties, engineered with materials like UV-stabilized nylon or polypropylene, are designed to resist moisture, chemicals, and environmental degradation. Their durability and adaptability make them indispensable across industries and daily life. Below are key applications where these ties excel.

2025-10-08

Surface treatment of anti-slip plastic cable ties

Plastic zip ties are essential for securing items, but their smooth surfaces can sometimes lead to slippage, especially under tension or in wet conditions. This compromises both functionality and safety, particularly in applications like construction, automotive repairs, or outdoor installations. By applying specialized surface treatments, manufacturers can significantly improve the grip and durability of zip ties, ensuring they stay firmly in place even in challenging environments.

2025-10-08

Plastic cable tie design with reduced wear

Plastic zip ties are widely used for securing items, but frequent movement, vibration, or exposure to abrasive surfaces can lead to premature wear, reducing their lifespan and reliability. By incorporating thoughtful design elements, manufacturers can create zip ties that resist wear more effectively, ensuring consistent performance even in demanding environments.

2025-09-10

Space-saving plastic cable ties application

Plastic zip ties are versatile tools for organizing and securing items, but their potential to save space is often overlooked. In environments where every inch matters—such as workshops, offices, or storage areas—strategic use of zip ties can streamline layouts, reduce clutter, and improve accessibility.