10

2025

-

11

The high-temperature resistance of Nylon 66 plastic cable ties

Author:

High-Temperature Resistance of Nylon 66 Plastic Cable Ties: Performance and Applications

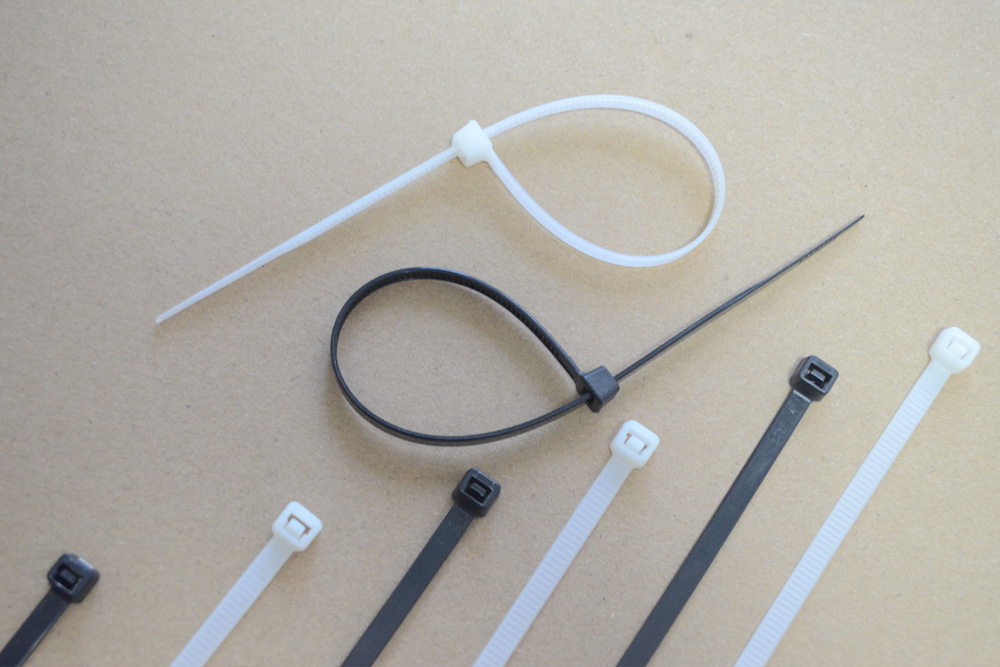

Nylon 66 plastic cable ties, widely used in industrial and engineering applications, are renowned for their robust mechanical properties and environmental resilience. Among these, their high-temperature resistance stands out as a critical factor enabling their deployment in demanding environments. This article explores the thermal stability, operational limits, and real-world applications of nylon 66 cable ties under elevated temperatures.

Thermal Stability and Degradation Mechanisms

Nylon 66, a polyamide derived from adipic acid and hexamethylenediamine, exhibits a glass transition temperature (Tg) around 50–60°C and a melting point (Tm) near 260°C. However, its practical operational range is influenced by molecular structure and additives. Standard nylon 66 cable ties typically maintain mechanical integrity in continuous-use scenarios up to 85°C, with short-term exposure tolerances extending to 130°C for specialized variants.

At elevated temperatures, two primary degradation pathways emerge:

- Thermal Oxidation: Prolonged exposure to temperatures above 85°C accelerates oxidation, leading to chain scission and embrittlement.

- Hydrolysis: In humid environments, moisture absorption weakens intermolecular forces, reducing tensile strength and elongation at break.

To mitigate these effects, manufacturers incorporate stabilizers such as antioxidants and UV absorbers, enhancing longevity in harsh conditions.

Performance Under Extreme Conditions

High-Temperature Variants

Certain nylon 66 formulations are engineered for extreme heat resistance. For instance, VO-grade flame-retardant cable ties meet UL94 V-0 standards, maintaining non-flammability even at 130°C. These variants are critical in electrical enclosures, aerospace systems, and automotive engine compartments, where fire safety and thermal stability are paramount.

Low-Temperature Flexibility

While high-temperature resistance is a focus, nylon 66’s performance at low temperatures is equally noteworthy. Standard grades remain flexible down to -40°C, with specialized cold-resistant versions operating at -60°C. This dual capability makes them versatile for applications spanning Arctic expeditions to desert operations.

Industry-Specific Applications

Automotive and Aerospace

In automotive manufacturing, nylon 66 cable ties secure wiring harnesses near engine components, where temperatures can exceed 100°C. Their resistance to vibration, chemicals, and thermal cycling ensures reliability over a vehicle’s lifespan. Similarly, aerospace applications leverage their lightweight strength and flame retardancy for cable management in aircraft cabins and engine bays.

Electronics and Electrical Engineering

The electronics sector relies on nylon 66 cable ties for bundling cables in power distribution units, data centers, and renewable energy systems. Their insulation properties (dielectric strength >15 kV/mm) and compatibility with soldering processes make them indispensable for high-voltage installations.

Industrial Machinery and Construction

In heavy machinery, nylon 66 cable ties withstand friction and heat generated by moving parts, while construction sites use them for securing scaffolding or temporary structures. Their UV resistance ensures outdoor durability, even in sunlight-exposed environments.

Comparative Analysis with Alternative Materials

Nylon 66 outperforms many plastics in high-temperature scenarios:

- Polypropylene (PP): Limited to 50°C, PP cable ties soften and lose tensile strength above this threshold, restricting them to low-heat applications.

- Polyester (PET): While PET offers UV resistance, its continuous-use temperature caps at 60°C, making it unsuitable for industrial heat sources.

- Polyethylene (PE): With a melting point below 120°C, PE cable ties are prone to deformation in moderate heat, limiting their utility to cold chains or packaging.

Nylon 66’s balance of heat resistance, mechanical strength, and chemical inertness positions it as a premium choice for mission-critical applications.

Practical Considerations for High-Temperature Use

- Temperature Ratings: Select cable ties rated for the maximum anticipated temperature, accounting for both ambient and operational heat sources.

- Installation Environment: Avoid installing near exhaust systems or radiators without adequate thermal insulation.

- Load Capacity: High temperatures may reduce tensile strength; derate the working load by 20–30% in extreme heat.

- Storage Conditions: Store cable ties in cool, dry places to prevent pre-installation degradation.

For instance, a study on automotive wiring harnesses revealed that nylon 66 cable ties exposed to 120°C for 500 hours retained 85% of their original tensile strength, compared to just 40% for PP alternatives.

Future Innovations in Thermal Resistance

Research is underway to enhance nylon 66’s high-temperature performance through:

- Nanocomposite Additives: Incorporating graphene or carbon nanotubes to improve thermal conductivity and stability.

- Bio-Based Nylon: Developing sustainable variants from renewable resources without compromising heat resistance.

- Smart Coatings: Applying thermal-responsive polymers that self-adjust to temperature fluctuations.

These advancements aim to extend nylon 66’s dominance in high-stakes environments while reducing environmental impact.

Nylon 66 plastic cable ties remain a cornerstone of modern engineering due to their exceptional high-temperature resilience, mechanical robustness, and adaptability. By understanding their thermal limits and selecting appropriate grades, industries can ensure reliable performance in even the most challenging conditions. As material science evolves, these humble fasteners will continue to play a vital role in securing the infrastructure of tomorrow.

plastic cable ties

Hot News

2025-11-10

The high-temperature resistance of Nylon 66 plastic cable ties

Nylon 66 plastic cable ties, widely used in industrial and engineering applications, are renowned for their robust mechanical properties and environmental resilience. Among these, their high-temperature resistance stands out as a critical factor enabling their deployment in demanding environments. This article explores the thermal stability, operational limits, and real-world applications of nylon 66 cable ties under elevated temperatures.

2025-11-10

Classification and characteristics of plastic cable ties materials

Plastic cable ties, widely used in industries ranging from electronics to automotive and construction, are essential for securing cables, bundling items, and ensuring safety. The choice of material significantly impacts their performance, durability, and environmental resistance. This article delves into the primary plastic materials used in cable ties and their defining characteristics.

2025-11-07

Adjustable plastic cable ties for selection

Plastic cable ties are indispensable for securing, organizing, and bundling materials, but their adjustability—the ability to modify tension or reuse them—varies widely based on design features and intended use. Selecting ties with optimal adjustability requires evaluating factors like tension control, reuse potential, and environmental adaptability. This guide explores the technical elements that influence how flexibly a cable tie can be managed.

2025-11-07

When choosing plastic cable ties, it is important to consider whether they are easy to cut

Plastic cable ties are engineered to provide secure fastening, but their resistance to cutting varies based on material composition, structural design, and intended use. Understanding these factors is crucial for applications requiring controlled cutting, whether for safety, maintenance, or temporary installations. This guide explores the technical elements influencing how easily a cable tie can be severed.