10

2025

-

10

Features of easy-to-operate plastic cable ties

Author:

Key Features of Easy-to-Use Plastic Cable Ties for Enhanced Efficiency

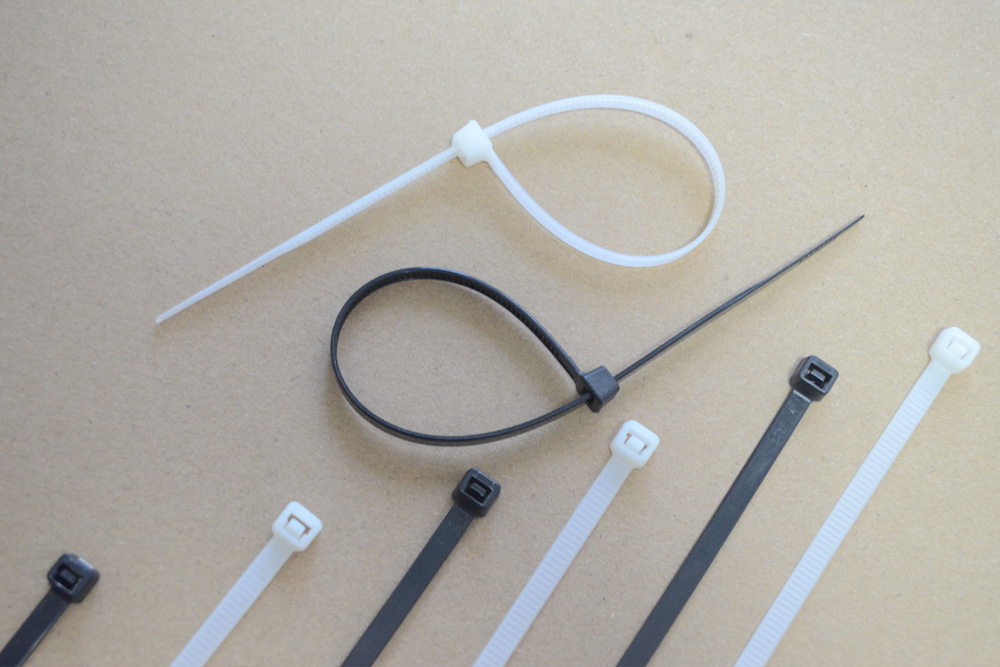

Plastic cable ties, also known as zip ties or bundling straps, are indispensable tools across industries ranging from electronics to logistics. Their popularity stems from a blend of functionality, durability, and user-friendly design. Below, we explore the core attributes that make these ties a go-to solution for secure and efficient bundling.

Mechanical Performance and Material Durability

Plastic cable ties are engineered to withstand diverse environmental conditions while maintaining structural integrity. The most common materials include nylon-66 and polypropylene (PP), each offering distinct advantages:

- Nylon-66: Renowned for its high tensile strength and resistance to abrasion, nylon-66 ties can endure temperatures from -40°C to 85°C. They exhibit excellent chemical resistance, though prolonged exposure to strong acids or phenols may degrade performance. Their self-locking mechanism ensures a tight grip without slippage, making them ideal for automotive wiring, aerospace components, and outdoor installations.

- Polypropylene (PP): Lightweight and cost-effective, PP ties are often used for lighter loads such as packaging or temporary bundling. They offer moderate tensile strength and flexibility, with operating temperatures ranging from 0°C to 60°C. PP ties are less resistant to UV exposure compared to nylon, limiting their use in prolonged outdoor applications.

The choice of material directly impacts the tie’s longevity and suitability for specific tasks. For instance, nylon’s resilience to moisture and chemicals makes it preferable for marine or industrial settings, while PP’s affordability suits short-term or indoor projects.

Design Innovations for User Convenience

Modern plastic cable ties incorporate design elements that prioritize ease of use without compromising security:

- One-Way Locking Mechanism: The teeth on the tie’s body engage with a pawl in the head, creating a non-reversible lock. This ensures the tie tightens securely with minimal effort, eliminating the need for additional tools. Users can adjust tension by pulling the tail until the desired firmness is achieved.

- Ergonomic Head Shapes: Rounded or contoured heads reduce hand fatigue during prolonged use. Some models feature a tapered design for easier insertion into tight spaces, such as behind equipment panels or within dense cable clusters.

- Releasable Variants: For applications requiring frequent adjustments, releasable ties include a lever or tab that temporarily disengages the lock. This allows users to reposition or remove the tie without cutting it, saving time and material costs.

These innovations streamline workflows in settings like data centers, where technicians must manage hundreds of cables daily. The ability to quickly secure and release ties enhances productivity while maintaining order.

Versatility Across Industries and Applications

Plastic cable ties adapt to a wide array of use cases, driven by their material properties and customizable features:

- Electronics and IT: Nylon ties with flame-retardant coatings (UL 94V-2 rating) are critical for organizing wires in servers, routers, and consumer devices. Their insulation properties prevent short circuits, while compact sizes accommodate dense circuitry.

- Automotive and Aerospace: High-temperature-resistant nylon ties withstand engine heat and vibration, securing hoses, sensors, and wiring harnesses. Their lightweight nature reduces vehicle weight, contributing to fuel efficiency.

- Agriculture and Construction: UV-stabilized PP ties resist degradation from sunlight and moisture, making them suitable for outdoor projects like securing irrigation pipes or temporary fencing.

- Retail and Logistics: Colored or printed ties enable quick identification of shipments, while heavy-duty PET (polyester) ties provide the strength needed for palletizing goods.

Customization options, such as varying lengths, widths, and colors, further expand their utility. For example, fluorescent ties improve visibility in low-light environments, while biodegradable variants address environmental concerns in temporary applications.

Environmental Resilience and Longevity

The durability of plastic cable ties is closely tied to their resistance to environmental stressors:

- Chemical Resistance: Nylon ties exhibit strong resistance to oils, greases, and most solvents, making them suitable for industrial machinery or automotive fluids. PP ties, while less chemically robust, resist water and mild acids, ideal for food packaging or agricultural use.

- Temperature Stability: Nylon’s ability to maintain performance across extreme temperatures ensures reliability in freezers (-40°C) or desert climates (up to 85°C). PP ties, however, may become brittle below freezing, limiting their use in cold storage.

- UV Protection: Additives in nylon and PP formulations mitigate UV degradation, prolonging the ties’ lifespan in outdoor settings. This is crucial for applications like solar panel installations or outdoor signage.

By selecting ties matched to environmental conditions, users can avoid premature failure and reduce waste. For instance, a construction site in a humid region would benefit from nylon ties with anti-corrosion coatings, while a warehouse storing perishables might opt for PP ties to minimize chemical contamination risks.

Conclusion

Plastic cable ties derive their widespread adoption from a harmonious blend of mechanical strength, user-centric design, and adaptability. Whether securing critical infrastructure or organizing everyday items, these ties offer a reliable, cost-effective solution. As industries evolve, advancements in materials science and ergonomic design will continue to enhance their performance, ensuring their relevance in an increasingly complex world.

plastic cable ties

Previous Page

Next Page

Previous Page

Next Page

Hot News

2025-10-10

Advantages of customizable plastic cable ties

Customizable plastic cable ties have become a cornerstone in industries requiring precision, efficiency, and brand differentiation. Unlike standard off-the-shelf options, these ties offer flexibility in design, material, and functionality, enabling businesses to address unique challenges. Below, we explore the key benefits of opting for customizable solutions.

2025-10-10

Features of easy-to-operate plastic cable ties

Plastic cable ties, also known as zip ties or bundling straps, are indispensable tools across industries ranging from electronics to logistics. Their popularity stems from a blend of functionality, durability, and user-friendly design. Below, we explore the core attributes that make these ties a go-to solution for secure and efficient bundling.

2025-10-09

Insect-proof plastic cable ties

Plastic cable ties, essential for organizing cables and securing equipment, face unique challenges in environments prone to insect activity. Standard ties may degrade when exposed to bites, secretions, or nesting behaviors of pests, leading to premature failure. Insect-resistant plastic cable ties address these issues through specialized material formulations, offering enhanced durability and reliability. Below, we explore the key material properties that make these ties suitable for pest-prone settings.

2025-10-09

Advantages of dust-proof plastic cable ties

Plastic cable ties, commonly known as zip ties, are indispensable tools across industries due to their versatility and cost-effectiveness. When designed with dust-resistant properties, these ties gain additional benefits that enhance their performance in environments prone to particulate contamination.