07

2025

-

09

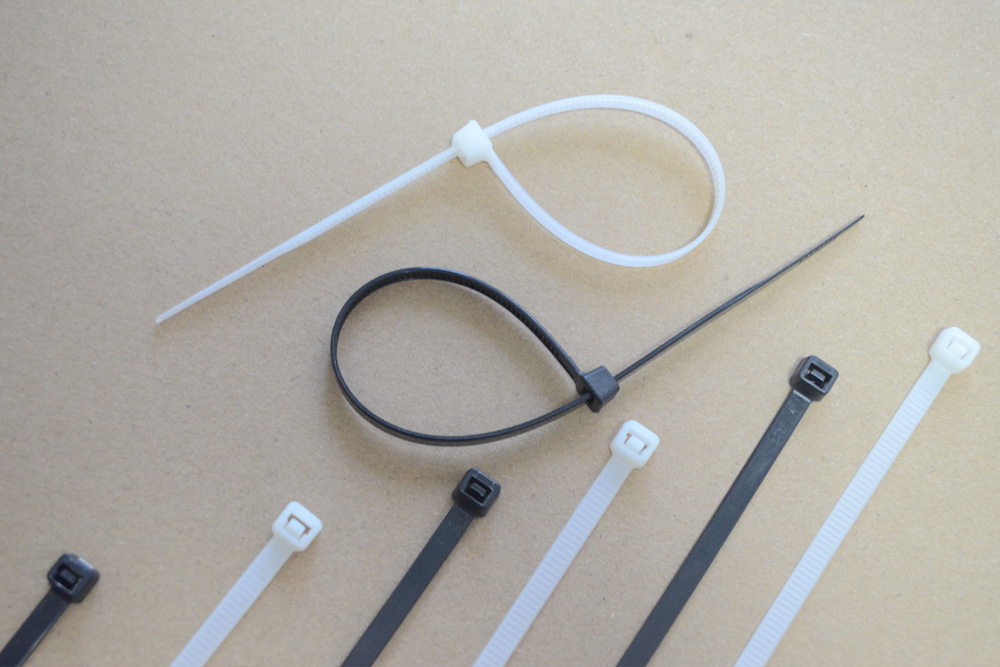

Plastic cable tie material with strong load-bearing capacity

Author:

High-Tensile Plastic Zip Tie Materials for Demanding Applications

Plastic zip ties are engineered to balance flexibility and strength, but certain applications demand materials capable of withstanding extreme tension, environmental stress, or repetitive loading. The choice of material directly impacts a zip tie’s tensile strength, durability, and resistance to factors like UV exposure, chemicals, or temperature fluctuations. Below are robust plastic materials commonly used in high-performance zip ties, each tailored to address specific challenges in industrial, construction, or heavy-duty settings.

Nylon 6/6: The Standard for High Tensile Strength

Nylon 6/6 is the most widely used material for plastic zip ties due to its exceptional balance of strength, stiffness, and thermal stability. This polyamide resin is engineered to resist deformation under tension, making it ideal for applications requiring secure fastening of heavy loads. Its molecular structure, composed of repeating amide bonds, creates a rigid framework that distributes stress evenly across the strap, preventing localized failure. Nylon 6/6 zip ties typically achieve tensile strengths ranging from 18 kg to over 100 kg, depending on their width and thickness, enabling them to secure everything from automotive components to industrial machinery.

The material’s resistance to abrasion and wear further enhances its longevity in high-friction environments. For example, in manufacturing plants where zip ties are used to bundle moving parts or vibrating equipment, nylon 6/6 maintains its integrity without fraying or cracking. Its low moisture absorption rate compared to other nylons minimizes swelling or weakening when exposed to humidity, ensuring consistent performance in both indoor and outdoor settings. Additionally, nylon 6/6 can be modified with glass fibers or other reinforcements to increase its tensile strength by up to 50%, catering to ultra-demanding applications like aerospace or marine engineering.

Chemical resistance is another hallmark of nylon 6/6, allowing it to withstand exposure to oils, fuels, and mild acids without degrading. This property makes it suitable for automotive wiring harnesses, where ties may contact engine fluids, or agricultural equipment, where they endure contact with fertilizers and pesticides. While prolonged exposure to strong acids or bases can cause degradation, standard nylon 6/6 zip ties perform reliably in most industrial and commercial environments, offering a cost-effective solution for high-tension fastening.

Polyethylene (PE): Flexibility Meets Moderate Strength

Polyethylene, particularly high-density polyethylene (HDPE), is chosen for zip ties requiring a balance of flexibility and moderate tensile strength. Unlike nylon, which is inherently rigid, HDPE’s linear polymer chains allow it to bend without cracking, making it ideal for applications involving irregular shapes or dynamic movement. HDPE zip ties are commonly used in landscaping to secure plants or trellises, where the strap must contour to organic surfaces without snapping. Their ability to absorb impacts without shattering also makes them suitable for bundling pipes or conduits in construction, where ties may experience accidental drops or collisions.

HDPE’s resistance to UV radiation is superior to many other plastics, thanks to stabilizers added during manufacturing. This ensures the material retains its strength and color when exposed to sunlight for extended periods, a critical feature for outdoor applications like fencing, signage, or temporary structures. Unlike nylon, which can become brittle in cold temperatures, HDPE remains pliable, allowing it to function in environments as low as -50°C without losing ductility. This cold-weather performance is valuable in refrigeration units, cold storage facilities, or northern climates where traditional materials might fail.

While HDPE’s tensile strength (typically 10–30 kg) is lower than nylon’s, it compensates with chemical inertness, resisting corrosion from salts, solvents, and alkaline substances. This property is advantageous in marine applications, where ties are submerged in seawater or exposed to salt spray, or in chemical processing plants handling non-reactive fluids. HDPE zip ties are also recyclable, aligning with sustainability goals in industries seeking to reduce plastic waste without compromising functionality.

Polypropylene (PP): Lightweight and Resistant to Fatigue

Polypropylene is a lightweight thermoplastic prized for its fatigue resistance and ability to withstand repetitive bending or flexing. Zip ties made from PP are often used in applications involving cyclic loading, such as securing cables in data centers where vibrations from servers or HVAC systems create constant movement. PP’s semi-crystalline structure absorbs energy without developing cracks, ensuring the tie remains intact even after thousands of flex cycles. This durability is further enhanced by the material’s low coefficient of friction, which reduces wear when ties rub against surfaces or other components.

PP zip ties excel in environments requiring hygiene and chemical resistance, such as food processing or pharmaceutical manufacturing. The material is non-toxic and can be sterilized, making it safe for bundling ingredients or medical tubing. Its resistance to acids, alcohols, and chlorinated cleaners ensures it won’t degrade when exposed to sanitizing agents, a common challenge in cleanroom environments. PP’s low water absorption rate also prevents microbial growth, a critical factor in applications where contamination must be minimized.

While PP’s tensile strength (around 10–25 kg) is modest compared to nylon, its lightweight nature (density 0.9 g/cm³) makes it suitable for applications where weight is a concern, such as aerospace or automotive interiors. PP ties are also less prone to stress cracking than other plastics when exposed to tensile loads and environmental stressors simultaneously, a phenomenon known as environmental stress cracking (ESC). This reliability under combined stressors ensures they perform consistently in real-world conditions, where ties may face both tension and chemical exposure.

Stainless Steel-Reinforced Hybrid Materials for Extreme Loads

For applications demanding maximum tensile strength and durability, hybrid materials combining plastic with stainless steel or carbon fiber are employed. These zip ties feature a plastic strap embedded with metal or fiber reinforcements, creating a composite structure capable of withstanding forces exceeding 200 kg. The stainless steel core provides rigidity and resistance to cutting or sawing, making these ties suitable for securing valuable assets or in high-security environments. The outer plastic layer protects the metal from corrosion while maintaining the tie’s ease of use, allowing it to be installed without specialized tools.

Hybrid zip ties are often used in infrastructure projects, such as anchoring utility poles or stabilizing scaffolding, where failure could result in catastrophic damage. Their ability to resist both tension and shear forces makes them indispensable in earthquake-prone regions, where ties must endure lateral movements without breaking. The metal reinforcement also prevents elongation under load, ensuring the tied bundle remains taut even during prolonged stress. While these ties are heavier and more expensive than standard plastic variants, their unmatched strength justifies their use in critical applications where safety is paramount.

From automotive assembly lines to offshore drilling platforms, the choice of material for plastic zip ties is dictated by the specific demands of the application. By selecting materials like nylon 6/6 for high tension, HDPE for flexibility, or PP for fatigue resistance, engineers and technicians can ensure reliable fastening in even the most challenging environments. Hybrid solutions further expand the possibilities, offering ultra-strong options for applications where failure is not an option.

plastic cable ties

Previous Page

Previous Page

Hot News

2025-09-10

Space-saving plastic cable ties application

Plastic zip ties are versatile tools for organizing and securing items, but their potential to save space is often overlooked. In environments where every inch matters—such as workshops, offices, or storage areas—strategic use of zip ties can streamline layouts, reduce clutter, and improve accessibility.

2025-09-10

Durable plastic cable tie material

Plastic zip ties are widely used across industries for their simplicity and effectiveness in securing items, but not all materials offer the same level of durability. Choosing the right material is essential for applications that require resistance to environmental factors, chemical exposure, or physical stress.

2025-09-09

Selection of plastic cable ties with good aesthetic appeal

Plastic zip ties are no longer just functional tools for bundling cables or securing items—they now play a role in maintaining visual harmony in professional and personal environments. Whether used in office setups, retail displays, or home organization projects, selecting zip ties with an attractive appearance can elevate the overall look of a space.

2025-09-09

Advantages of adjustable plastic cable ties

Adjustable plastic zip ties revolutionize traditional bundling methods by offering flexibility in tension control, reusability, and adaptability to varying object sizes. Unlike standard zip ties, which lock permanently once tightened, adjustable variants allow users to modify grip strength, reposition the tie, or reuse it for multiple applications.