Metal Cable Glands

Category:

Detailed

Metal Cable Glands | IP68 Waterproof Brass & Stainless Steel Cable Connectors

(M Thread/PG Thread, Wide Cable Range, Corrosion-Resistant for Harsh Environments)

Product Highlights

✅ Industrial-Grade Durability – Made from brass or 304/316 stainless steel, resistant to saltwater, oils, acids, and solvents.

✅ IP68 Waterproof Seal – Superior protection against dust, moisture, and high-pressure water ingress.

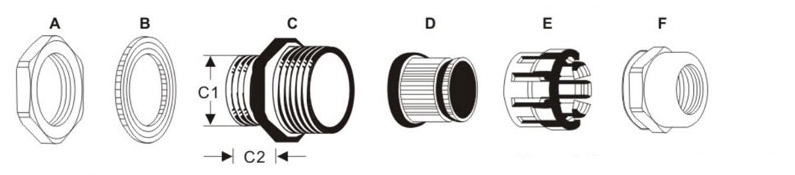

✅ Wide Cable Compatibility – Claw-and-seal design accommodates a broad cable diameter range without disassembly.

✅ Easy Installation – Cable threads directly through and tightens instantly, saving time and labor.

✅ Extreme Temperature Resistance – Stable performance from -30°C to +100°C (ideal for outdoor/industrial use).

Technical Specifications

| Feature | Details |

|---|---|

| Material | Brass / 304 or 316 Stainless Steel (anti-corrosion) |

| Thread Type | M Thread or PG Thread (specify when ordering) |

| Protection Grade | IP68 (submersible and dustproof) |

| Packaging | 5pcs/bag, 20pcs/bag, 50pcs/bag, 100pcs/bag – bulk discounts available. |

| ITEM NO. | CABLE RANGE | THREAD O.D. | MOUNTING HOLE DIA | THREAD LENGTH | JOINT LENGTH | SPANNER SIZE |

| MM | MM | MM | GL(MM) | H(MM) | MM | |

| M8×1 | 5.5-2 | 8 | 8-8.2 | 5 | 16 | 12 |

| M10×1 | 6.-3 | 10 | 10-10.2 | 7 | 19 | 14 |

| M12×1.5 | 6.5-3 | 12 | 12-12.2 | 7 | 19 | 14 |

| M14×1.5 | 8-4 | 14 | 14-14.2 | 7 | 19 | 17 |

| M16×1.5 | 8-4 | 16 | 16-16.2 | 8 | 20 | 18 |

| M18×1.5 | 10-5 | 18 | 18-18.2 | 8 | 21 | 20 |

| M20×1.5 | 12-6 | 20 | 20-20.2 | 8 | 22 | 22 |

| M22×1.5 | 14-10 | 22 | 22-22.2 | 8 | 23 | 24 |

| M24×1.5 | 14-10 | 24 | 24-24.2 | 9 | 25 | 24/27 |

| M25×1.5 | 14-10 | 25 | 25-25.2 | 9 | 25 | 24/27 |

| M27×1.5 | 18-13 | 27 | 27-27.2 | 9 | 27 | 30 |

| M28×1.5 | 18-13 | 28 | 28-28.2 | 9 | 27 | 30 |

| M30×1.5 | 18-13 | 30 | 30-30.2 | 9 | 29 | 30/32 |

| M32×1.5 | 22-15 | 32 | 32-32.2 | 10 | 29 | 35 |

| M36×1.5 | 25-18 | 36 | 36-35.2 | 10 | 31 | 40 |

| M40×1.5 | 25-18 | 40 | 40-40.2 | 11 | 31 | 40/45 |

| M42×1.5 | 30-22 | 42 | 42-42.2 | 11 | 35 | 45 |

| M48×1.5 | 33-25 | 48 | 48-48.2 | 11 | 37 | 50/52 |

| M50×1.5 | 38-32 | 50 | 50-50.2 | 12 | 37 | 50/52 |

| M54×1.5 | 38-32 | 54 | 54-54.2 | 12 | 38 | 57 |

| M60×1.5 | 44-37 | 60 | 60-60.2 | 13 | 38 | 64 |

| M63×1.5 | 44-37 | 63 | 63-63.2 | 13 | 38 | 64/68 |

| PG7 | 6.5-3 | 12.5 | 12.5-12.7 | 7 | 19 | 14 |

| PG9 | 8-4 | 15.2 | 15.2-15.4 | 8 | 20 | 17 |

| PG11 | 10-5 | 18.6 | 18.6-18.8 | 8 | 21 | 20/21 |

| PG13.5 | 12-6 | 20.4 | 20.4-20.6 | 8 | 22 | 22 |

| PG16 | 14-10 | 22.5 | 22.5-22.7 | 9 | 23 | 24 |

| PG19 | 14-10 | 25 | 25-25.2 | 9 | 25 | 24/27 |

| PG21 | 18-13 | 28.3 | 28.3-28.5 | 9 | 27 | 30 |

| PG25 | 22-15 | 32 | 32-32.2 | 10 | 29 | 35 |

| PG29 | 25-18 | 0.37 | 37-37.2 | 11 | 31 | 40 |

| PG36 | 33-25 | 47 | 47-47.2 | 12 | 37 | 50 |

| PG42 | 38-32 | 54 | 54-54.2 | 13 | 38 | 57 |

| PG48 | 44-37 | 59.3 | 59.3-59.5 | 14 | 38 | 64 |

| PG63 | 52-42 | 72 | 72 | 15 | 42 | 77 |

Key Advantages of Our Metal Cable Glands

🔹 Secure Grip – Reinforced claws and seals hold cables firmly, preventing slippage or strain damage.

🔹 Chemical Resistance – Withstands saltwater, weak acids, alcohol, grease, and industrial solvents.

🔹 No Disassembly Needed – Streamlined one-step installation reduces assembly time.

🔹 Safety Certified – Complies with international electrical and mechanical safety standards.

Applications

✔ Marine & Offshore – Harsh saltwater environments (316 stainless steel recommended).

✔ Oil & Gas – Resistant to petroleum-based fluids and high-pressure conditions.

✔ Industrial Machinery – Cable entry protection for control panels, motors, and sensors.

✔ Renewable Energy – Solar/Wind farm equipment with UV and weather exposure.

✔ Automotive & Rail – Vibration-proof cable fixation in engines and transport systems.

Why Choose Our Cable Glands?

✔ Precision Engineering – Smooth threading and uniform clamping force to prevent cable damage.

✔ Global Compliance – Meets IEC/EN standards for industrial electrical safety.

✔ Custom Options – Available in brass (cost-effective) or stainless steel (high-corrosion resistance).

FAQ

❓ Can these glands be reused?

→ Yes! The threaded design allows for repositioning or reuse if undamaged.

❓ How do I select the right thread type (M vs. PG)?

→ M Thread (metric) is common in Europe/Asia; PG Thread (German standard) suits older equipment. Check your device specifications.

❓ What’s the difference between 304 and 316 stainless steel?

→ 316 SS has higher molybdenum content for extreme corrosion resistance (e.g., marine/chemical plants).

Related product series

Counselling