28

2025

-

10

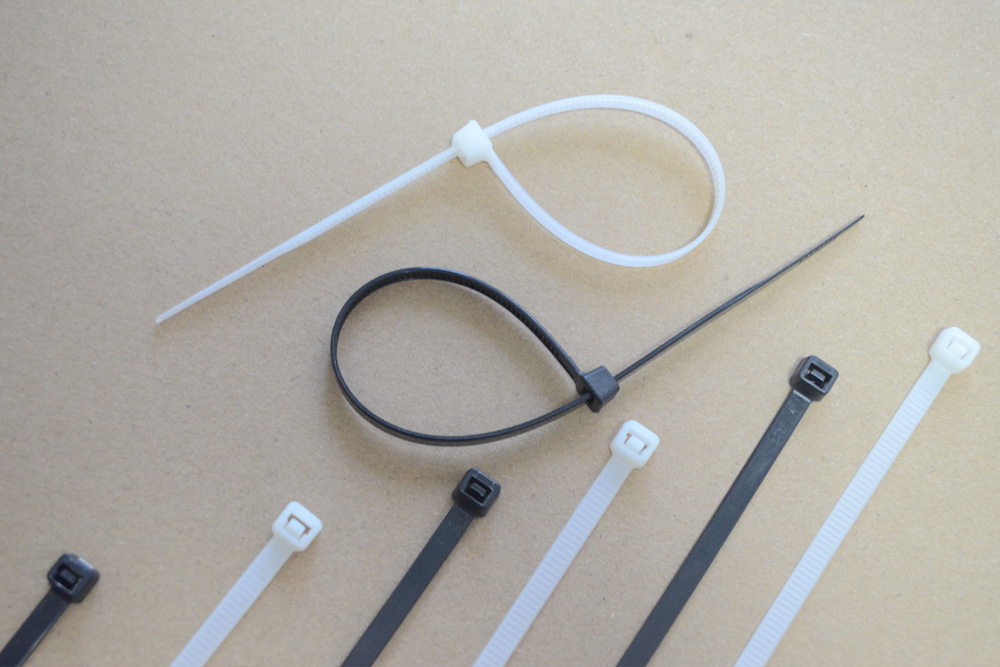

Key points for choosing plastic cable ties

Author:

Key Considerations for Selecting Plastic Cable Tie Materials: Durability, Environment, and Application Fit

Choosing the right material for plastic cable ties is essential to ensure longevity, safety, and performance across diverse environments. The material impacts resistance to temperature, chemicals, UV rays, and physical stress, making it critical to align the tie’s composition with the demands of the application. Below are detailed guidelines for selecting materials based on environmental exposure, load requirements, and industry-specific needs.

Nylon: The Most Common Choice for General Applications

Nylon is the most widely used material for cable ties due to its balance of strength, flexibility, and cost-effectiveness. It performs well in moderate temperatures and resists abrasion, making it suitable for indoor electrical wiring, office cable management, and light-duty bundling. Standard nylon ties are ideal for environments without extreme heat, moisture, or chemical exposure.

However, nylon’s performance varies with its grade. Untreated nylon may degrade under prolonged UV exposure, leading to brittleness. For outdoor use, opt for UV-stabilized nylon, which incorporates additives to resist sunlight-induced breakdown. Similarly, nylon ties exposed to oils or solvents should feature chemical-resistant coatings to prevent swelling or weakening.

Nylon Material Variations

- Standard Nylon: Best for dry, temperature-controlled indoor settings like offices or homes.

- UV-Stabilized Nylon: Essential for outdoor installations exposed to sunlight.

- Chemical-Resistant Nylon: Required in workshops or industrial areas with oil, grease, or solvents.

Polypropylene: Lightweight and Cost-Effective for Low-Stress Uses

Polypropylene (PP) is a lighter, more affordable alternative to nylon, though it sacrifices some strength and heat resistance. PP ties are ideal for bundling lightweight items such as holiday lights, garden hoses, or non-critical packaging materials. Their flexibility makes them easy to handle, but they are prone to cracking in cold temperatures and melting at lower heat thresholds than nylon.

PP ties are unsuitable for high-tension applications or environments exceeding 150°F (65°C). However, they excel in cold storage facilities or seasonal outdoor use where temperatures remain above freezing. For added durability, some PP ties include UV inhibitors, though their lifespan under direct sunlight is shorter than nylon.

Polypropylene Application Scenarios

- Cold Environments: Use in refrigerated areas or winter outdoor projects where temperatures stay above 32°F (0°C).

- Lightweight Bundling: Secure small cords, fabric, or lightweight hoses without heavy loads.

- Short-Term Use: Temporary installations where longevity isn’t a priority.

Stainless Steel: The Ultimate Choice for Corrosive and High-Temperature Environments

Stainless steel cable ties offer unmatched durability in harsh conditions, including marine settings, chemical plants, and high-temperature industrial zones. Unlike plastic ties, stainless steel resists corrosion from saltwater, acids, and alkalis, making it indispensable for offshore oil rigs, food processing facilities, and coastal installations.

These ties also withstand extreme heat, remaining functional at temperatures exceeding 1000°F (538°C). However, stainless steel ties are heavier, less flexible, and require specialized tools for tightening. They are overkill for most residential or office uses but critical in environments where plastic ties would fail.

Stainless Steel Advantages

- Corrosion Resistance: Prevents rust in saltwater, chemical, or humid settings.

- Heat Tolerance: Maintains strength in high-temperature applications like exhaust systems or foundries.

- Longevity: Outlasts plastic ties in environments with constant physical or chemical stress.

Heat-Resistant Polymers: Specialized Options for Extreme Conditions

For applications involving intermittent or sustained high temperatures, heat-resistant polymers like polyamide 6.6 (PA66) or polyphenylene sulfide (PPS) offer enhanced thermal stability. PA66 ties withstand temperatures up to 350°F (177°C), making them suitable for engine compartments, industrial ovens, or automotive wiring. PPS ties, rated for temperatures exceeding 500°F (260°C), are used in aerospace or foundry applications.

These materials resist melting and deformation under heat but may be brittle at low temperatures. They also cost more than standard nylon, so reserve them for environments where thermal stability is non-negotiable. Always verify the tie’s continuous operating temperature rating to avoid failure.

Heat-Resistant Polymer Use Cases

- Automotive Engines: Secure battery cables or exhaust system components.

- Industrial Machinery: Bundle hoses or wires near heat sources like furnaces or motors.

- Aerospace: Use in areas exposed to extreme temperatures during flight.

Chemical-Resistant Materials: Preventing Degradation in Harsh Substances

In environments with frequent exposure to chemicals, oils, or solvents, selecting a chemically inert material is critical. Standard nylon or polypropylene may swell, crack, or lose strength when in contact with aggressive substances. Instead, opt for materials like polyethylene (PE) or specialized nylon blends with chemical-resistant coatings.

PE ties resist acids, bases, and hydrocarbons, making them suitable for laboratories, chemical storage areas, or automotive workshops. Some nylon ties incorporate additives to enhance resistance to specific chemicals, such as hydraulic fluids or cleaning agents. Always cross-reference the tie’s chemical compatibility chart with the substances it will encounter.

Chemical Resistance Strategies

- Acidic Environments: Use PE ties or nylon with acid-resistant additives.

- Oil Exposure: Choose nylon or PE ties rated for hydrocarbon resistance.

- Solvent Contact: Avoid polypropylene; opt for chemically treated nylon or PE.

Biodegradable Options: Sustainable Choices for Temporary Applications

For eco-conscious projects or temporary installations, biodegradable cable ties made from materials like PLA (polylactic acid) or starch-based polymers offer a sustainable alternative. These ties break down naturally within months to years, reducing plastic waste in landfills.

Biodegradable ties are weaker than traditional plastics and degrade faster under UV light or moisture. They are best suited for short-term uses, such as event decorations, agricultural vines, or packaging. Avoid them in permanent installations or environments where longevity is required.

Biodegradable Tie Applications

- Events: Secure banners, signs, or temporary lighting.

- Agriculture: Train plant vines or bundle crops during harvest.

- Packaging: Close bags or boxes for single-use shipping.

By evaluating the application’s environmental stressors—such as heat, chemicals, or UV exposure—users can select a material that balances performance, cost, and sustainability. The right choice ensures secure bundling while minimizing the risk of premature failure or environmental harm.

plastic cable ties

Previous Page

Previous Page

Hot News

2025-10-31

Selection of corrosion resistance performance of plastic cable ties

The corrosion resistance of plastic cable ties is primarily determined by their polymer base and additive formulations. Polyamide 66 (PA66), a common material for industrial ties, exhibits moderate resistance to hydrocarbons, oils, and weak acids. However, its performance diminishes in the presence of strong acids, bases, or chlorinated solvents. To enhance durability, manufacturers incorporate stabilizers such as hindered amine light stabilizers (HALS) and UV absorbers, which prevent degradation from environmental stressors.

2025-10-31

Selection of fire resistance performance for plastic cable ties

The fire resistance of plastic cable ties is primarily determined by their material composition and certification standards. The most widely recognized metric is the UL94 flame rating system, which categorizes materials based on their burning behavior. For instance, ties labeled as UL94 V-0 exhibit superior fire resistance compared to V-2 rated variants.

2025-10-30

Environmental protection requirements for plastic cable ties

Global environmental regulations have significantly tightened restrictions on hazardous substances in plastic packaging materials, including cable ties. The Toxic Packaging Clearinghouse (TPCH) in the United States updated its model legislation in 2025, imposing strict limits on harmful chemicals.

2025-10-30

Analysis of the Cost Performance of Plastic Cable ties

The core material of plastic cable ties determines their durability and application scope. Nylon (polyamide) variants, such as PA6 and PA66, are widely regarded for their high tensile strength, chemical resistance, and ability to withstand temperatures ranging from -40°C to 85°C.